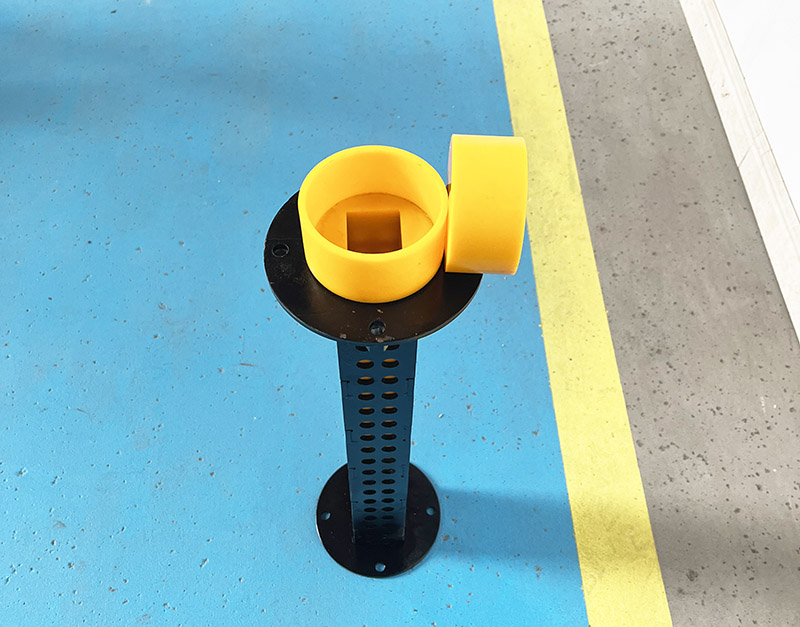

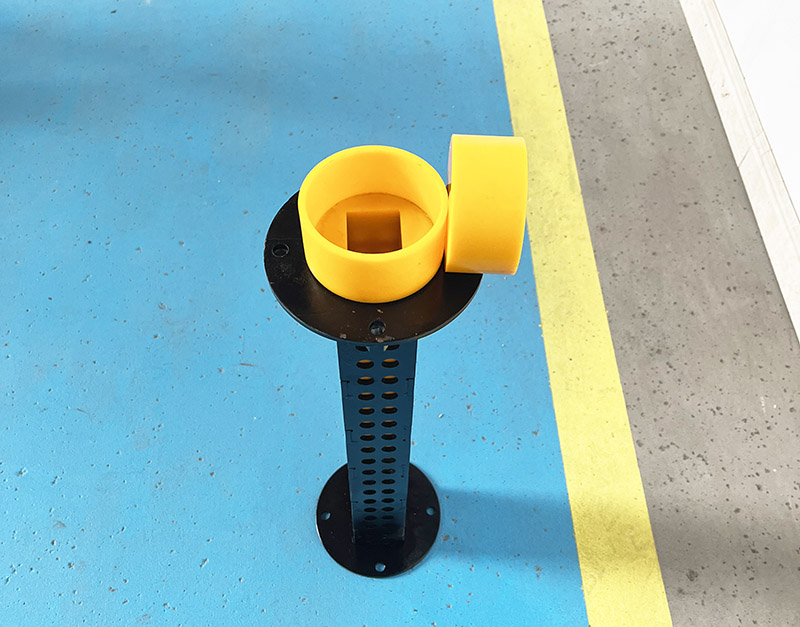

Isostatic Pressing molds/bags FOR Semiconductor Materials

Isostatic pressing molds, isostatic pressing molds for semiconductor materials, and isostatic pressing rubber sleeve-covered molds for isostatic pressing of silicone materials are made of polymer elastomer materials and have better strength than traditional isostatic pressing rubber molds. Longer service life and more precise molding effect. In the molding of new materials, such as semiconductor material isostatic pressing molds, silicon material isostatic pressing molds, special ceramic isostatic pressing molds, high-performance precision isostatic pressing molding, users invariably choose polyurethane isostatic pressing molds. The polymer polyurethane material specially developed for isostatic pressing molding is different from ordinary polyurethane. It is better adapted to various wet isostatic pressing equipment and dry bag isostatic pressing equipment, and meets the various harsh requirements of imported equipment and domestic equipment. Require.

Generally, brake fluid or anhydrous glycerin is used. These two liquids have very little compressibility and can transmit almost all the pressure to the elastic mold. During isostatic pressing, the pressure transmitted by the liquid medium is equal in all directions. The deformation generated by the elastic mold when subjected to the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the green body is evenly stressed, and the density distribution is uniform, and the product performance is greatly improved.

Isostatic pressure refers to the relationship between the relative dielectric constant and loss of the sample and various parameters, and the effects of isostatic pressure and bias voltage on the ferroelectric/antiferroelectric phase transition and antiferroelectric/paraelectric phase transition of antiferroelectrics are obtained. (PE) The law of phase change temperature influence. During isostatic pressing, the powder or workpiece is generally placed in a bag, and then the bag is evacuated, degassed and sealed, and then the entire sealed component is placed in the cylinder of the isostatic press, and is pressed using hydraulic or hydraulic pressure. Air pressure densifies the powder or workpiece.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber mold Plastic mold Polyurethane Product Pu product