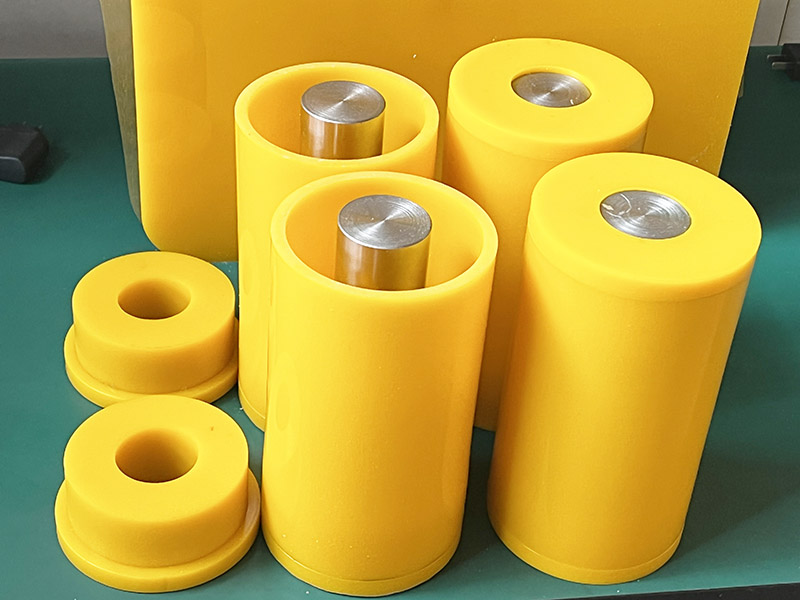

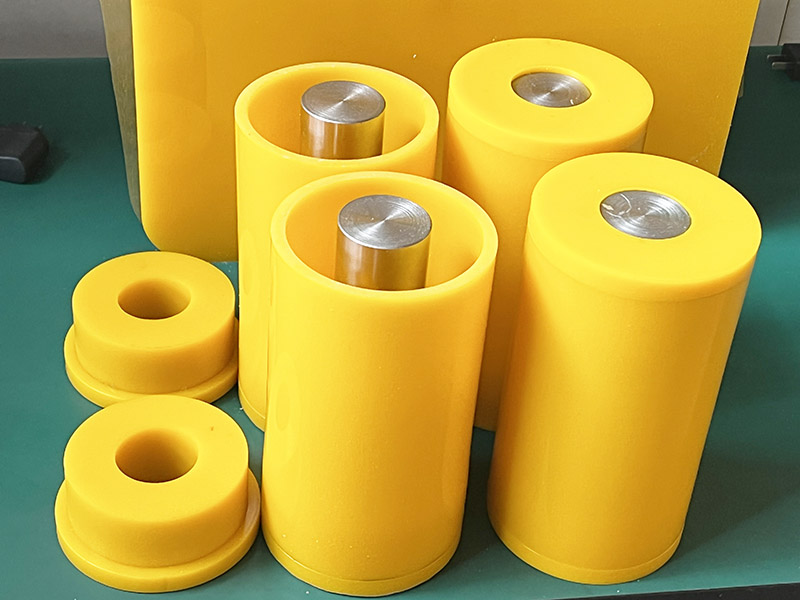

The Advantages of Polyurethane Cold Isostatic Pressing Molds

The reasons why cold isostatic pressing rubber sleeve molds are replaced by polyurethane PU isostatic pressing leather sleeve molds are: mold strength, molding effect, service life, ease of demoulding, wide application, etc. The special polyurethane material isostatic rubber sleeve mold has the advantages of rolling in terms of performance and cost-effectiveness! The polyurethane polymer material specially developed for isostatic molds has the characteristics of good plasticity, good elasticity, oil resistance, water resistance and oxidation aging resistance. Reflected in isostatic pressing production, it means precise molding, smooth surface and long service life. Depending on the usage, targeted solutions include design, manufacturing of rubber sleeves, tooling and lifting fixtures. Of course, ordinary polyurethane product companies cannot achieve those advantages by using so-called isostatic pressing molds crudely made from conventional polyurethane materials.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

Compare to traditional rubber cold isostatic pressing bags, the polyurethane CIP bags have significant advantages. As a new polymer material, polyurethane products feature smooth surface, wearing-resistant, anti-fatigue, low deformation rate. The surface of pressed products with polyurethane bags is much smoother than that pressed with rubber bags, thus it possesses better looks and less postprocessing is required. It’s an ideal tool for powder material forming by press process, which can help a company reduce cost and increase efficiency.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber mold Plastic mold Polyurethane Product Pu product