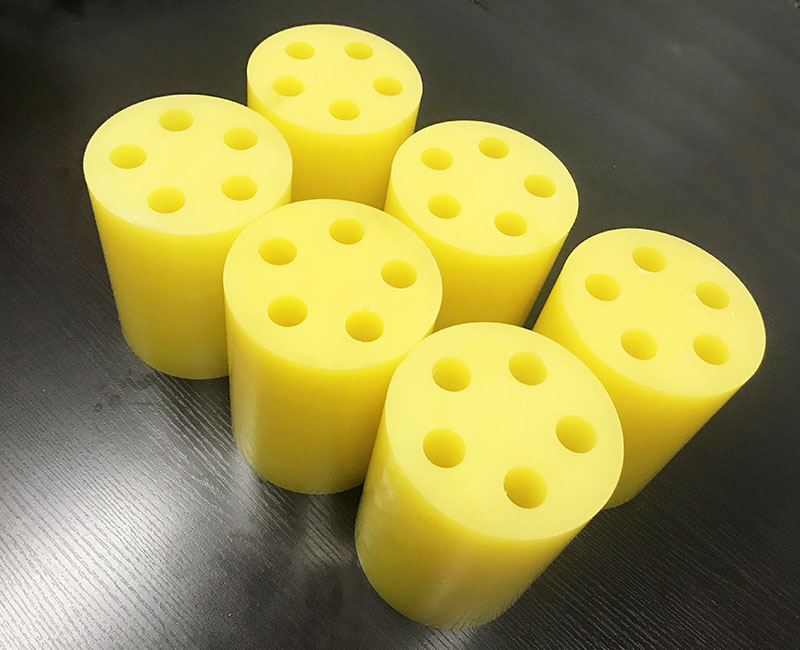

Dry-bag Isostatic Pressing Bags for Ceramic

Categories: DIP powder forming mold

Application: Dry-bag Isostatic Pressing Bags for Ceramic

InquiryMain description:

Dry-bag Isostatic Pressing Bags for Ceramic

Dry-bag Isostatic Pressing Bags for Ceramic

Dry-bag Isostatic Pressing Bags for Ceramic

Isostatic pressing is to add granulated ceramic materials into the mold. The material of the mold is generally plastic or rubber with certain elasticity. The granulated porcelain material in the mold is compacted and formed. There are two methods of isostatic pressing: cold isostatic pressing and hot isostatic pressing, and cold isostatic pressing is divided into wet and dry.

Cold isostatic pressing

Cold isostatic pressing technology is at room temperature, usually rubber or plastic is used as the jacket mold material, and liquid is used as the pressure medium, which is mainly used for powder material molding, and provides green bodies for further sintering, forging or hot isostatic pressing processes. The general working pressure is 100~630MPa.

Dry bag isostatic pressing is relative, that is, the mold is not all in the dry isostatic press of high-pressure liquid medium, but semi-fixed, so the addition of blanks and blanks All extractions are performed in a dry state. When the dry mold bag is pressed and clamped by the upper and lower punches, the high-pressure liquid is input to the surrounding of the dry mold bag, so that the powder is shaped by uniform pressure.

Compared with traditional dry pressing, isostatic pressing has the following advantages:

1. The density of the green body is higher, generally about 10% higher than that of the dry pressing green body.

2. It can make blanks with large size or complex shape.

3. The green body has good strength, which is convenient for handling and direct machining.

4. The density of the green body is uniform in all directions, and the internal stress of the green body is small, which reduces defects such as cracking and delamination of the green body, and the deformation of the sintered product is small.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com