Isostatic Pressing Molds for Zirconia Ceramic Molding

Categories: DIP powder forming mold

Application: Isostatic Pressing Molds for Zirconia Ceramic Molding

InquiryMain description:

Isostatic Pressing Molds for Zirconia Ceramic Molding

Isostatic Pressing Molds for Zirconia Ceramic Molding

Isostatic Pressing Molds for Zirconia Ceramic Molding

Zirconia ceramic molding and processing Zirconia ceramic injection molding is a branch of modern powder injection molding technology, which has many special technical and technological advantages: it can be mass-produced quickly and automatically, and the process can be precisely controlled; because Flow filling makes the density of the green body uniform; no mechanical processing or only micro-processing is required, which reduces the preparation cost; due to high-pressure injection, the powder content in the mixture is greatly increased, reducing the shrinkage of sintering, making the product size accurate and controllable, and the tolerance can be controlled Up to 0.1%~0.2%, excellent performance; it can form complex shapes, with horizontal holes, inclined holes, concave-convex surfaces, threads, thin-walled, difficult-to-cut ceramic special-shaped parts, and has a wide range of application prospects.

Isostatic pressing of zirconia ceramics Isostatic pressing reduces the porosity of the powder mixture to produce a wide variety of shapes made from powder briquettes. These powder mixtures are compacted isostatically, with equal pressure in all directions. According to the production method of isostatic pressing, we can understand that it can be divided into hot isostatic pressing and cold isostatic pressing. Cold isostatic pressing works by applying external pressure to water or oil, which is then transferred to the sealed powder mixture. In addition to obtaining molded bodies with uniform density and no defects and complex shapes, high pressures up to 400MPa-500MPa can also be achieved. Therefore, the density of the molded body is further improved, and favorable conditions are created for subsequent sintering densification.

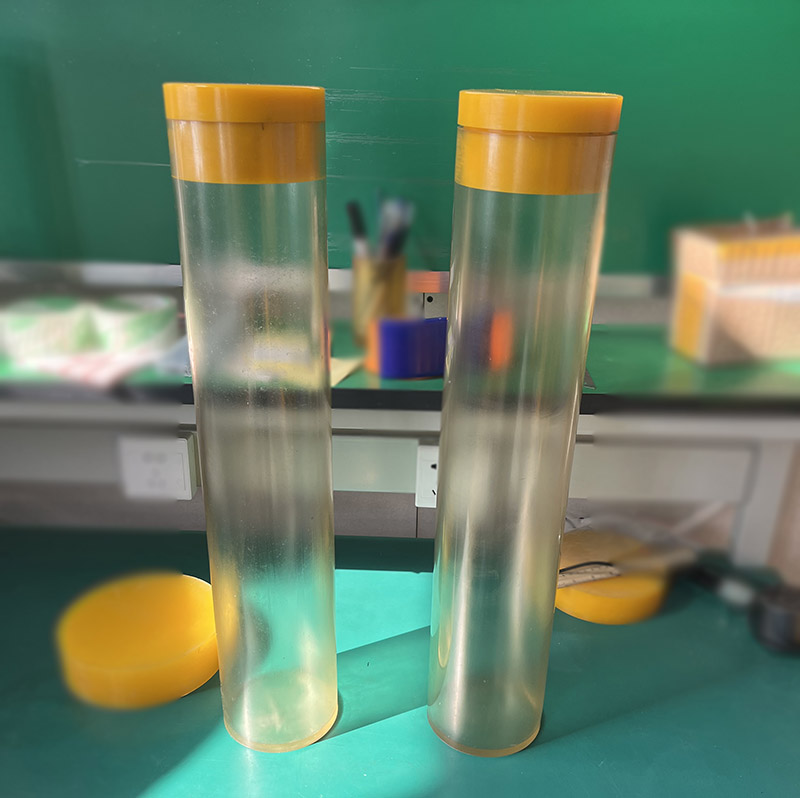

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

Polyurethane Isostatic Pressing Molding Molds/Bags

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com