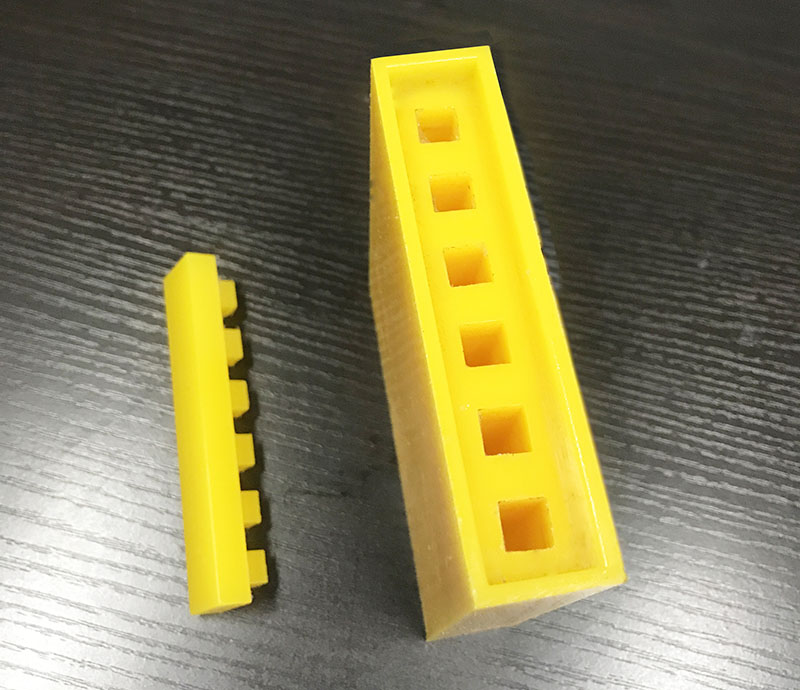

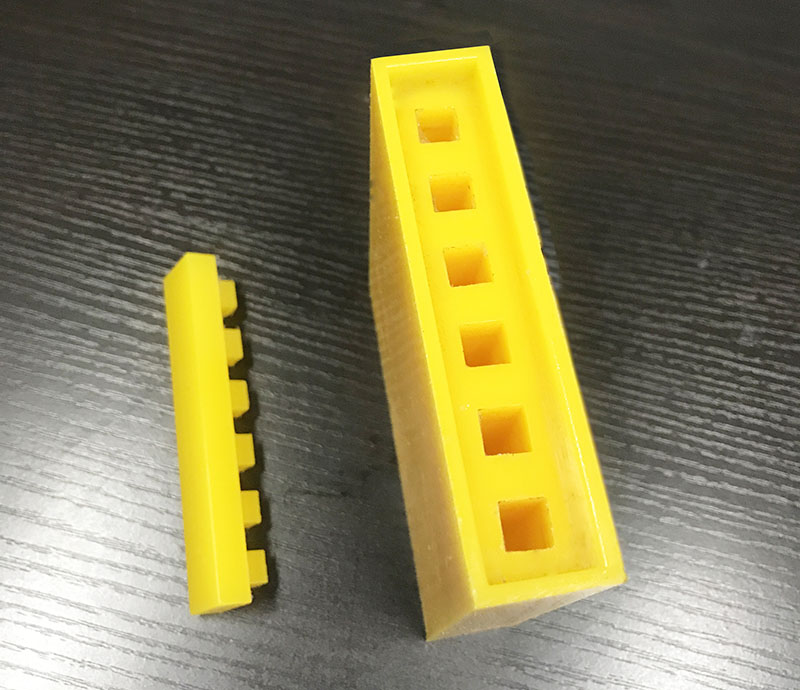

Whole Set of Wet-bag Isostatic Pressing Molds and Dry-bag Isostatic Pressing Modls

The typical process is to put the powder into an elastic soft cover (generally imported professional polyurethane material is better), the soft cover is sealed and put into a sealable container (cylinder), and the pressure of the liquid medium acts on the cover evenly On, and then the pressure is transmitted to the workpiece to achieve isostatic pressing. The commonly used liquid medium is a mixed emulsion of water and oil or oil, so it is called "hydrostatic pressure" and "oil static pressure". Cold isostatic pressing is mostly used in powder metallurgy to obtain powder preforms. In the mid-1930s, cold isostatic pressing began to be used to press tungsten, molybdenum and ceramic products. Compared with mechanical pressing, due to the high pressure of cold isostatic pressing and the uniform force on the workpiece, it is especially suitable for pressing large-sized powder products. The pressed powder product has the advantages of high density and uniform density, and the pressed powder does not need to add lubricants. The working pressure of the commonly used cold isostatic press can be as high as 6500kgf/cm2.

1. Wet bag isostatic pressing

Put the powder into a plastic bag, directly inject into the liquid pressure medium, and contact with the liquid. Therefore, it is called wet bag method. This method can change the shape and size of the plastic sheath arbitrarily, and the product has great flexibility and is suitable for small-scale production. Every time bagging and unloading operations are carried out, the production efficiency is not high, and continuous large-scale production cannot be carried out.

2. Dry bag isostatic pressing

The isostatic pressing mold is first placed in the cylinder and is not taken out during work. After the powder is put into another molding plastic bag, it is put into a pressurized rubber bag without contact with the liquid, so it is called the thousand bag method. This method can be operated continuously, that is, the upper cover is opened, the material is loaded from the hopper, and then the upper cover is closed and pressurized. When discharging, open the upper cover, and push the compact out from the top through the top rod at the bottom. The operation cycle is short, suitable for mass production. However, product specifications are limited because the pressurized plastic mold cannot be replaced frequently.

Isostatic pressing molds are used in isostatic pressing of new energy materials and graphite electrode materials, and can be customized for isostatic pressing of billets, cylinders, rings and various special-shaped parts, including isostatic pressing A complete set of solutions, such as holsters, isostatic mandrels, isostatic shaping tooling, and isostatic lifting fixtures, is an integrated solution that facilitates the isostatic pressing of powders for new energy materials.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold