Cold Isostatic Pressing Technology

Categories: CIP bags, CIP mold

Application: Cold Isostatic Pressing Technology

InquiryMain description:

Cold Isostatic Pressing Technology

Cold Isostatic Pressing Technology

Cold Isostatic Pressing Technology

Cold isostatic pressing technology refers to the technology of pressurizing the powder discharged from the molding machine at room temperature. This technology is mainly suitable for powder material molding and is one of the common powder metallurgy preparation processes. This technology can greatly improve the density and physical properties of the powder, and can prepare engineering materials with excellent mechanical properties, so it is widely used in aviation, automobiles and other fields.

Cold isostatic pressing requirements for powder

In order to obtain high-quality, high-density molded parts in the cold isostatic pressing process, the powder raw material needs to meet the following requirements:

1. Uniform particle size: The particle size of the powder should be moderate, too fine or too thick will affect the molding effect. Powders that are too fine are prone to agglomeration, while powders that are too coarse are difficult to obtain high density.

2. Regular shape: The shape of the powder should be regular to facilitate compact packing and molding.

3. Uniform distribution: The distribution of powder should be uniform to avoid stress concentration and damage.

4. Uniform mineral composition: The mineral composition in the powder should be evenly distributed to facilitate molding and subsequent processing.

5. High surface finish: The surface of the powder should have a high finish to reduce the resistance between the powders and help reduce friction.

Advantages and limitations of cold isostatic pressing

Cold isostatic pressing technology has its advantages and limitations in powder material processing. Key advantages include:

1. High precision: This technology enables highly precise machining.

2. Easy to realize automatic production: due to the simple operation steps of this technology, automatic production can be realized.

3. Wide application range: This technology can prepare various powder materials for molding, such as metal, non-metal, ceramics, etc.

4. The mold is easy to make and has a long service life.

The main limitations include:

1. Unable to achieve high-precision shape: Due to the characteristics of cold isostatic pressing, it is very difficult to achieve high-precision shape.

2. Higher cost: This technology requires the use of expensive molding machines, so the cost is higher.

3. High requirements for powder: As mentioned above, powder needs to have uniform and regular particle size and shape, so the requirements for powder are high.

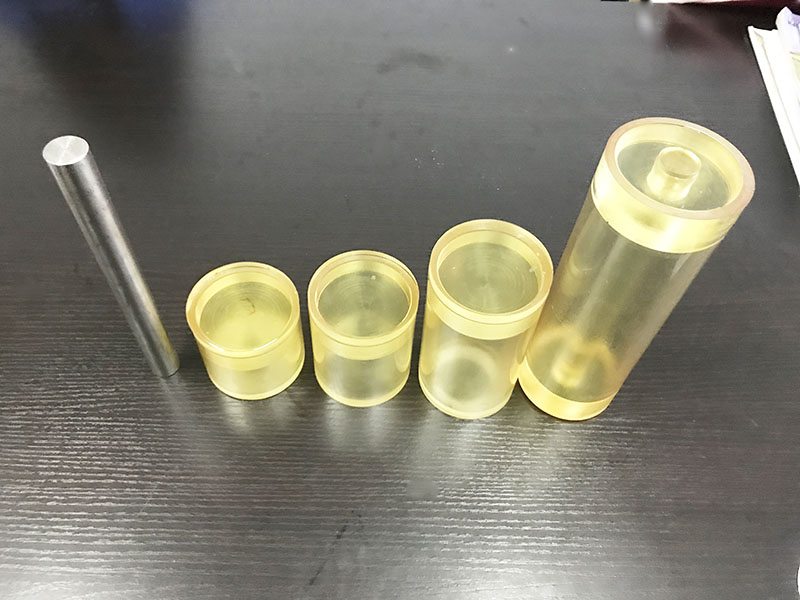

The Samples of cold isostatic pressing bags

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com