Isostatic Pressing Molds

Categories: Powder metallurgy bag mold

Application: Isostatic Pressing Molds

InquiryMain description:

Isostatic Pressing Molds

Isostatic Pressing Molds

Isostatic Pressing Molds

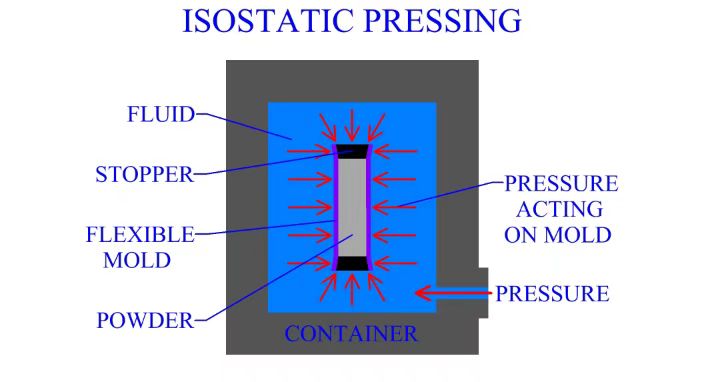

Isotactic molding is the molding method that plastic pellet material is loaded into a soft bag mold and then placed in high pressure fluid to make it a blank. In this method, the material pressure is uniform, and the blank has nothing to do with the mold shape. The obtained billet has no bubbles, uniform compression, and no debris during molding. It can be used for preforming polytetrafluoroethylene and ultra-high molecular weight polyethylene.

Isostatic forming is also called hydraulic forming. According to the process characteristics, it can be classified as a type of molding. But isostatic molding has its "personality". Often the problem that can not be solved by die molding can be successfully completed by isostatic molding. Isostatic forming was originally used in the ceramic industry, and then expanded to powder metallurgy industry. Until about 1960, it was applied to PTFE, ultra-high molecular weight polyethylene and other difficult to process polymer.

The basic principle of isostatic molding: according to PASCAL's theorem, the use of high pressure fluid to the same pressure to everywhere, so that easy "permeable" rubber bags (latex bags) expand or shrink, so that the polymer material between the bag and the molding wall is slowly and evenly compressed, the formation of the required shape of PTFE preformed products. Isostatic forming can be divided into three methods: internal hydraulic forming, external hydraulic forming and internal and external hydraulic forming. Isostatic molding has four characteristics: simple processing equipment, less investment, easy to form a production line; The mold has the advantages of simple structure, convenient operation and safe production. The preformed products are under uniform pressure, the quality can be guaranteed, and the qualified rate of preformed products is high; Compared with molding, it has less materials, low cost and good economic benefits.

A samples of iso bags

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com