Isostatic Pressing Molds for Isostatic Pressed Graphite

Categories: Isopressing mold

Application: Isostatic Pressing Molds for Isostatic Pressed Graphite

InquiryMain description:

Isostatic Pressing Molds for Isostatic Pressed Graphite

Isostatic Pressing Molds for Isostatic Pressed Graphite

Isostatic Pressing Molds for Isostatic Pressed Graphite

Isostatic pressed graphite is a new type of graphite material developed in the 1960s, which has a series of excellent properties. For example, the heat resistance of isostatic pressed graphite is good, in an inert atmosphere, with the increase of temperature, its mechanical strength not only does not decrease, but increases, reaching the highest value at about 2500℃; Compared with ordinary graphite, the structure is fine and dense, and the uniformity is good. The thermal expansion coefficient is very low, with excellent thermal shock resistance; Isotropy; Strong chemical corrosion resistance, good thermal and electrical conductivity; It has excellent machining properties.

Forming of isostatic pressed graphite

Different from ordinary extrusion molding and die molding, isostatic graphite is formed by cold isostatic pressing technology. The raw material pressed powder is filled into the rubber mold, through high-frequency electromagnetic vibration, so that the pressed powder is dense, sealed after vacuuming, discharge the air between the powder particles, put into a high pressure container with water or oil and other liquid medium, pressurized to 100-200 MPa, pressed into a cylindrical or rectangular product. According to PASCAL's principle, the pressure is added to the rubber mold through the liquid medium such as water, and the pressure in all directions is equal. In this way, the pressed powder particles in the mold are not oriented in the filling direction, but are compressed in an irregular arrangement, so that although the graphite is anisotropic in crystallographic properties, the isostatic pressed graphite is isotropic on the whole. In addition to columns and rectangles, there are also cylinders, crucibles and other shapes.

Isostatic molding machine has been widely used in advanced ceramics, powder metallurgy, Ndfeb magnetic materials, cemented carbide, aquatic products husking and seawater pressure testing and other industries. Due to the needs of high-end industries such as aerospace, nuclear industry, cemented carbide, and high voltage electromagnetic, isostatic pressure technology is developing very fast.

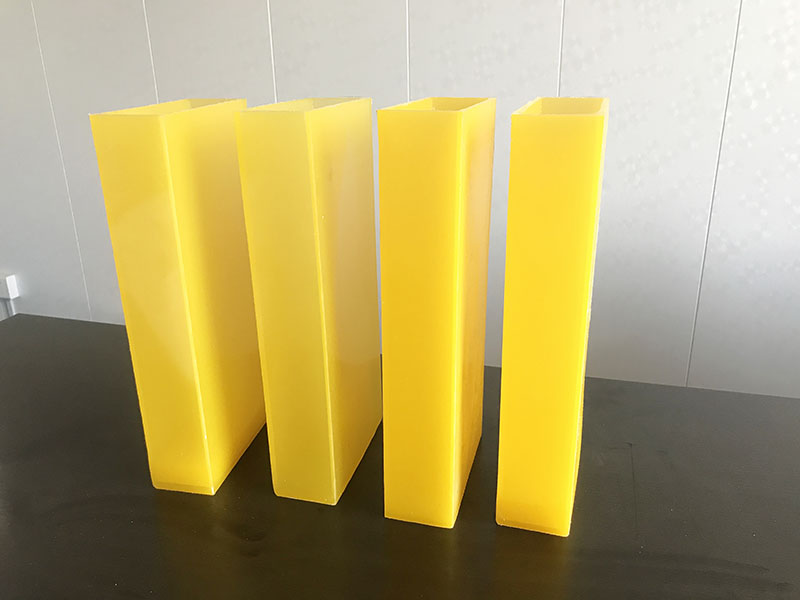

The Sample of ISO Molds for Isostatic Pressed Graphite

The Molding Pics

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com