Cold Isostatic Pressing Tooling for Powder Metallurgy

Categories: Powder metallurgy bag mold

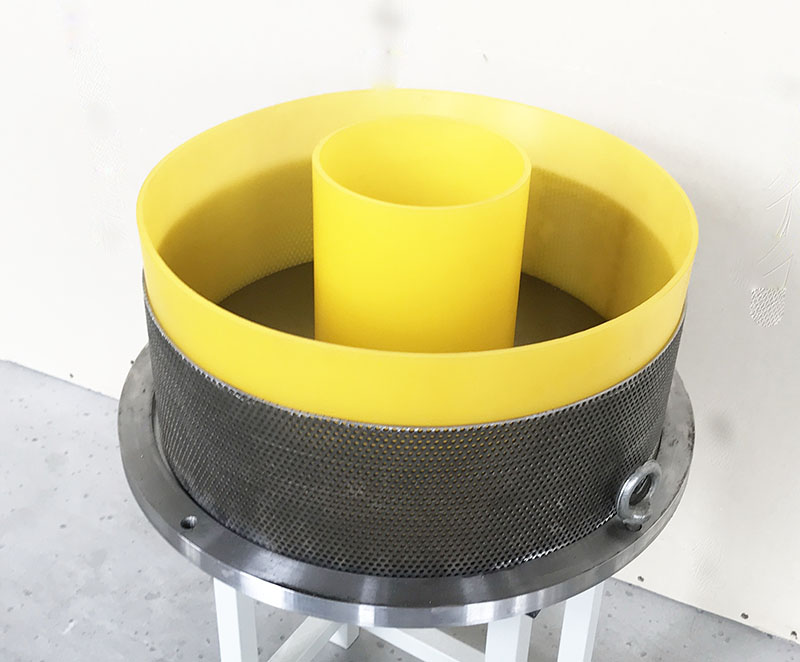

Application: Cold Isostatic Pressing Tooling for Powder Metallurgy

InquiryMain description:

Cold Isostatic Pressing Tooling for Powder Metallurgy

Cold Isostatic Pressing Tooling for Powder Metallurgy

Cold Isostatic Pressing Tooling for Powder Metallurgy

Powder metallurgy is the most advanced metal forming process. Powder metallurgy is a process that uses metal powder as raw material to manufacture metal materials, composite materials and various types of products through forming and sintering processes. The basic process includes four steps of raw material powder preparation, powder forming, sintering, and post-processing. The powder forming process includes pressing sintering, metal injection molding, hot or cold isostatic pressing, and metal additive manufacturing. Powder metallurgy has a development history of more than one hundred years, but with its advanced technology, it has always been at the forefront of the times and applied in emerging high-end fields. Compared with the traditional metallurgical process, powder metallurgy has the highest utilization rate of materials (up to 95%, while traditional machining is only 50%) and the lowest energy consumption (about 80% of the raw materials come from recycled waste). It is a state-of-the-art, green and low-cost Carbon, metal forming processes in line with the high-quality development trend.

The demand for metal powder will enter a period of accelerated growth in scale. For a long time, the powder metallurgy industry has been mainly driven by the application of the automotive market; in the next 10 years, new energy, aerospace, medical, electrical and electromagnetic, industrial and consumer products will jointly promote the accelerated development of the powder metallurgy industry, and the demand for metal powder will enter the scale period of accelerated growth.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com