Design and Manufacture of Isostatic Pressing Mold

Categories: DIP powder forming mold

Application: Design and Manufacture of Isostatic Pressing Mold

InquiryMain description:

Design and Manufacture of Isostatic Pressing Mold

Design and Manufacture of Isostatic Pressing Mold

Design and Manufacture of Isostatic Pressing Mold

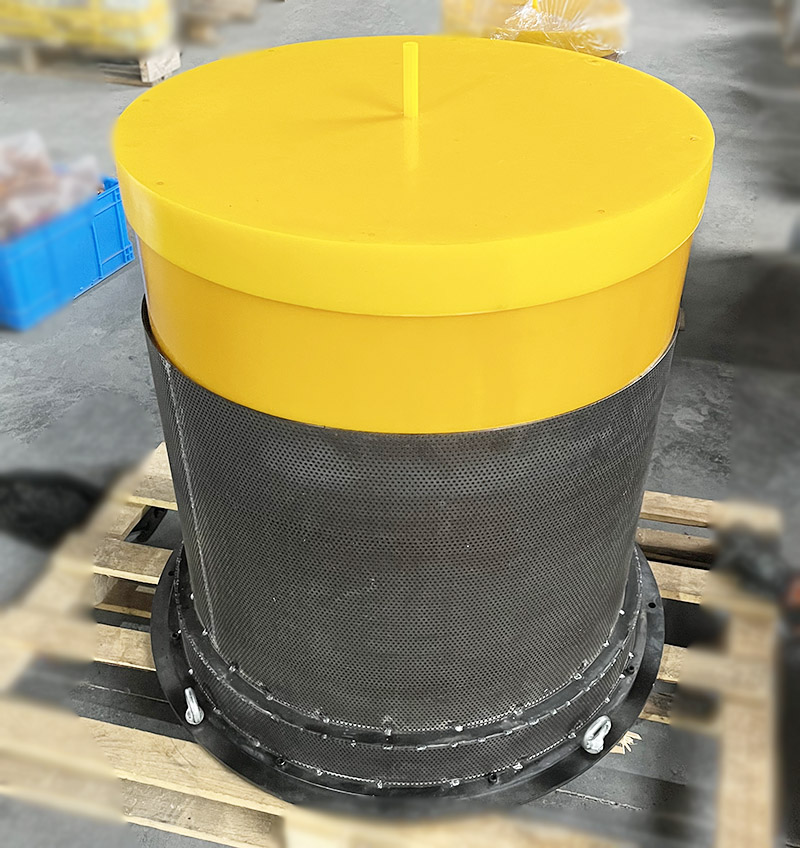

Press billet graphite, billet cemented carbide, polyurethane (imported raw material) isostatic pressing mold, good shape, long life, can be used in wet isostatic pressing machine and dry bag isostatic pressing equipment. Commonly used cold isostatic presses can be divided into screw type and frame type according to different container sealing structures. The screw-type cold isostatic press is simple in structure, but the operation is labor-intensive, and the thread wear is serious during use. It is usually an isostatic press with a small container (cylinder body); while the frame-type cold isostatic press is complicated in equipment, but Safe and reliable, easy to operate, usually a press with a larger container (cylinder).

In the isostatic pressing process, the characteristics of the powder, the filling density of the powder in the mold, and the structure of the mold have a great influence on the performance of the formed body, and the structural design of the isostatic pressing mold is very important. In the specific implementation of the isostatic pressing forming process, it is divided into direct isostatic pressing forming and molding-isostatic pressing combined forming process, and the direct isostatic pressing forming process is divided into internal pressure method and external pressure method according to the direction of pressure. pressure method. The designs of the molding dies and wrappers corresponding to these different methods also have their own characteristics.

Direct isostatic pressing is to fill and seal the powder directly in the mold cavity, and then directly place it in a liquid medium for pressurization; while the combined molding process of molding and isostatic pressing is to form a blank through a rigid mold in advance, and then The blank is sealed in a plastic envelope for isostatic pressing. The internal pressure method and external pressure method in the direct isostatic pressing process are mainly aimed at forming hollow tubular blanks.

Traditional isostatic pressing molds include isostatic pressing rubber molds, silicone molds and steel molds, and there are many problems in practical applications. As a new type of polymer material, polyurethane has many advantages such as wide range of hardness, high strength, wide range of performance adjustment, wear resistance, tear resistance, oil resistance, chemical resistance, and oxidation resistance.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com