CIP Mold

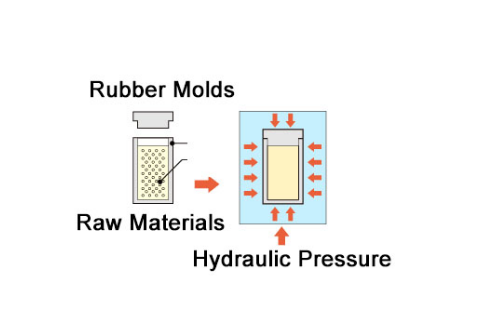

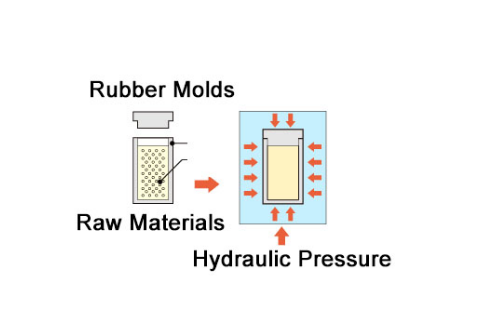

Cold isostatic pressing, usually using rubber or plastic as the mold jacket material, using liquid as the pressure transmission medium, exerts the same pressure on the powder blank in all directions, and presses it into a predetermined shape for the next step of sintering, forging or hot isostatic pressing process Provide blanks.

Isostatic pressing is to place the object to be processed in a specific mold, then put the mold with the workpiece into a closed container filled with liquid, gradually increase the pressure through the booster system, and transmit the pressure through the liquid to make the object The various surfaces of the mold are subjected to equal pressure, and under the constraints of the mold, the molding process takes place. During the compression process, the distance between the molecules of the actual workpiece is reduced and the density is increased, which changes the physical and even chemical properties of the compressed item.

Cold isostatic pressing includes wet bag cold isostatic pressing and dry bag isostatic pressing. Wet bag cold isostatic pressing involves suspending an elastic mold in a liquid. The dry bag isostatic pressing method is to fix the elastic mold in the high-pressure container and position it with a stopper.

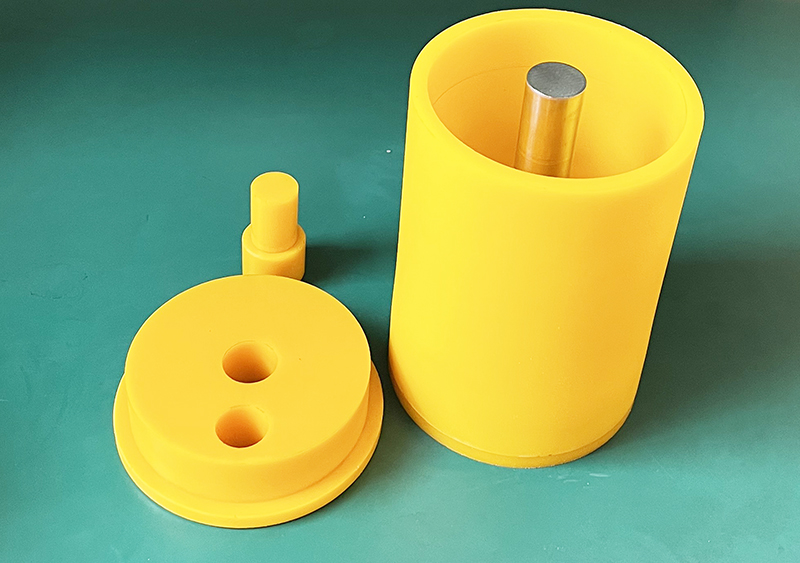

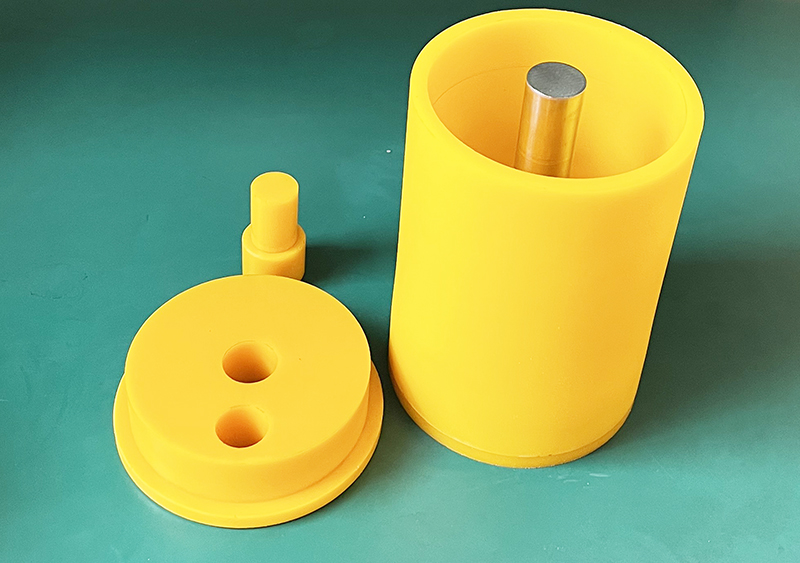

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold