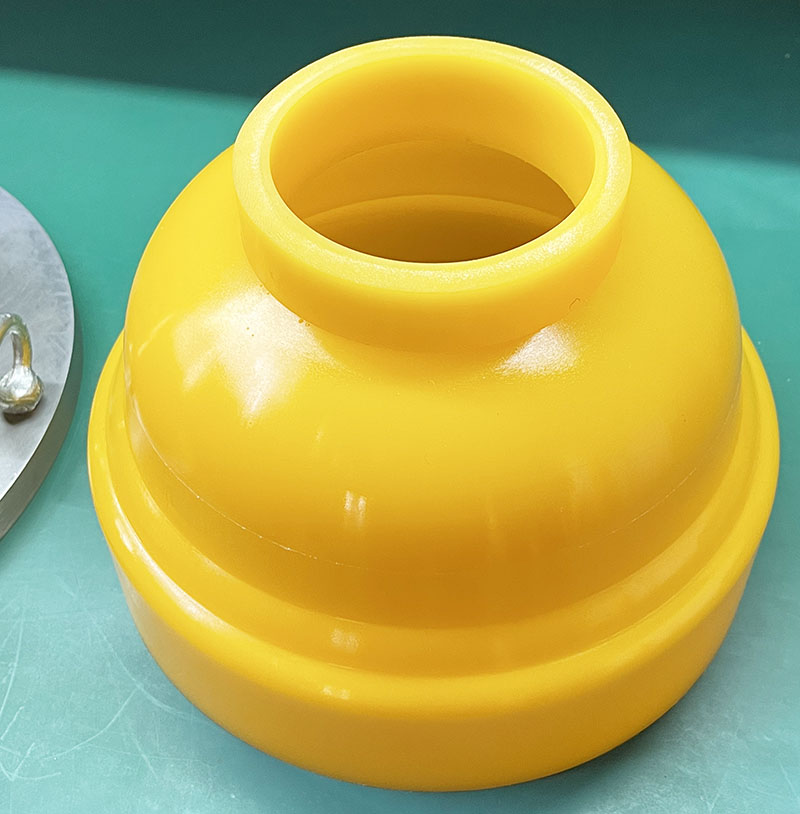

Isostatic Pressing Ceramic Mold

Categories: Isopressing mold

Application: Isostatic Pressing Ceramic Mold

InquiryMain description:

Isostatic Pressing Ceramic Mold

Isostatic Pressing Ceramic Mold

Isostatic Pressing Ceramic Mold

Isostatic pressing ceramic ball

Isostatic pressing, also known as hydrostatic pressing, is a molding method that utilizes the incompressibility of liquid media and the uniform transmission of pressure. In this method, the pre-pressed powder body is put into an elastic plastic or rubber sleeve, and then placed in a steel cylinder that can withstand high expansion force, and then the liquid is pumped into the body with a high-pressure pump. The powder in the rubber sleeve will be subjected to the same pressure in all directions, so as to be pressed into a green body of a certain shape. The ceramic ball prepared by the isostatic pressing process has good surface quality, no pores, uniform density, stable mechanical properties, and has significantly improved corrosion resistance, wear resistance, and erosion resistance.

The advantages of this molding method are conducive to obtaining ceramic ball products with excellent performance and greatly reducing the subsequent fine processing time. The small machining allowance greatly reduces the post-processing time. According to the size of the billet, the post-processing time can be reduced to about 25-30 days. After molding, the rough balls produced by the isostatic pressing process are of good quality, which can greatly improve the yield of ceramic balls. The passing rate of rough balls after processing can be guaranteed to be above 90%, and it can also reduce the invalid loss of grinding wheels such as grinding discs (used to grind defective products, and defective products waste consumables), greatly reducing the loss of grinding wheels and other consumables. Therefore, although the blank ball prepared by isostatic pressing is more than 30% more expensive than dry pressing, it can still greatly reduce the comprehensive processing cost of high-precision ceramic balls. For the blank, it can reduce the preparation cost by about 30%-40%. However, isostatic pressing molding equipment is expensive, and there is a problem of demoulding, which limits its application in large-scale industrial production.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com