Wet-bag Isostatic Pressing Mold and Dry-bag Isostatic Pressing Mold

Isostatic pressing is a powder molding process that uses products in a closed high-pressure vessel. It exerts the same pressure on the powder blank in all directions, so that the powder product has a uniform density distribution and particle structure. The process is mainly used for simple or complex-shaped parts that require uniform strength and crack resistance, as well as powder metallurgy products with large aspect ratios.

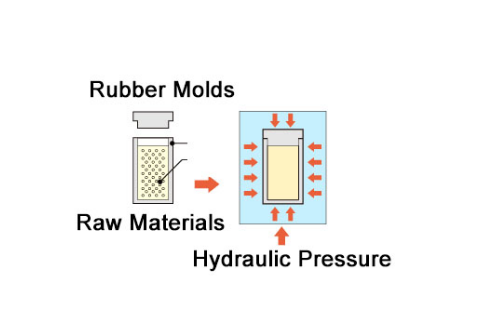

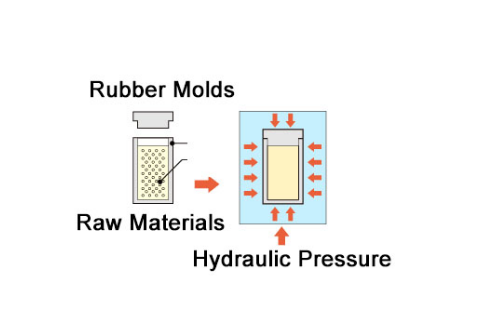

Cold isostatic pressing usually uses rubber or plastic as the mold material and liquid as the pressure transmission medium to apply the same pressure to the powder blank in all directions and press it into a predetermined shape for the next step of sintering, casting or hot isostatic pressing. Press to supply blanks.

Cold isostatic pressing is widely used in cemented carbide, powder metallurgy, high-speed steel, titanium and titanium alloys, refractory materials, graphite, crucibles, ceramics, rare earth permanent magnets, crystals, medicine and food. The powder material can be obtained with high density and excellent material homogeneity. Cold-pressed and isostatically pressed products are very conducive to machining, and can also produce products with particularly complex shapes.

There are two types of cold isostatic pressing: wet bag method and dry bag method

1. Wet bag isostatic pressing

Fill the powder into the liquid pressure medium directly, and contact with the liquid, so it is called wet bag method. This method can change the shape and size of the plastic sheath arbitrarily, and the product has great flexibility and is suitable for small-scale production. Every time bagging and unloading operations are carried out, the production efficiency is not high, and continuous large-scale production cannot be carried out.

2. Dry bag isostatic pressing

The rubber bag is first placed in the tank, and is not taken out during work. After the powder is put into another plastic bag, it is put into a pressurized rubber bag, which does not contact with the liquid, so it is called the thousand bag method. This method can be operated continuously, that is, open the upper cover, load material from the hopper, then cover the upper cover and pressurize it, and when discharging, open the upper cover, and push the green compact out from the upper side through the top rod at the bottom. It is suitable for mass production, but the product specifications are limited because the pressurized plastic mold cannot be replaced frequently.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold