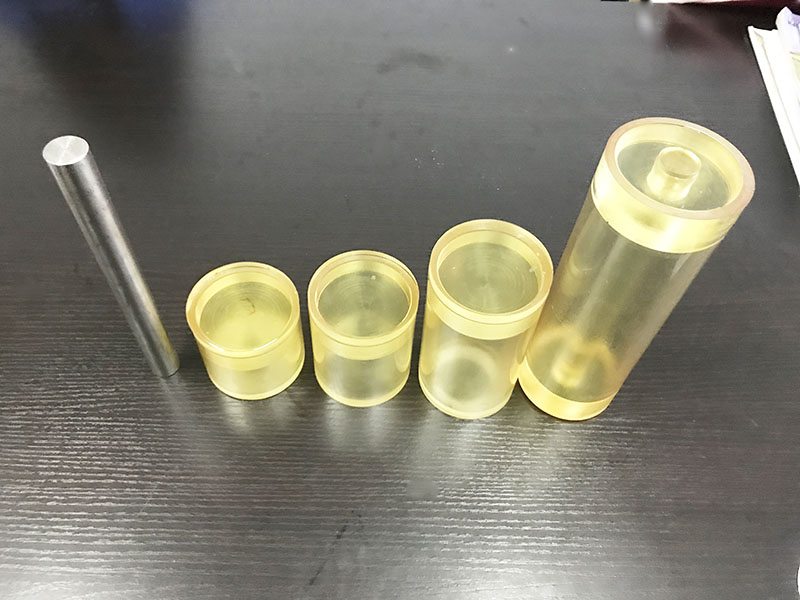

Polyurethane Cold Isostatic Pressing ITO Molds

Categories: CIP bags, CIP mold

Application: Polyurethane Cold Isostatic Pressing ITO Molds

InquiryMain description:

Polyurethane Cold Isostatic Pressing ITO Molds

Polyurethane Cold Isostatic Pressing ITO Molds

Polyurethane Cold Isostatic Pressing ITO Molds

ITO targets are widely used in photovoltaic field

Photovoltaic targets are mainly used to prepare thin films required in photovoltaic cells. Taking the HJT cell as an example, there is a TCO film layer in the structure of the HJT cell, which plays an important role in light transmission and conductivity. Using physical vapor deposition (PVD) technology, ions and atoms on the surface of the target are separated from the target to form a transparent conductive film on the substrate. Taking the perovskite battery structure as an example, the perovskite battery is composed of multilayer thin films and glass. For example, ITO thin films require photovoltaic targets for preparation.

ITO target is currently the main sputtering target for solar cells. Transparent conductive film is very important in thin-film batteries, and it undertakes the dual functions of light transmission and conduction. From the perspective of the advantages of the ITO target, indium tin oxide (ITO) is an N-type semiconductor material, which has the advantages of high electrical conductivity, high visible light transmittance, strong mechanical hardness and good chemical stability. Therefore, in the field of photovoltaics, ITO thin films made of ITO targets have better optical and electrical properties.

From the perspective of ITO target preparation methods, there are various preparation methods, and the advantages of cold isostatic pressing are prominent. There are mainly four methods for preparing ITO targets, namely hot pressing, hot isostatic pressing, room temperature sintering, and cold isostatic pressing. Advantages of cold isostatic pressing method for preparing ITO targets: 1) The pressure of cold isostatic pressing method is relatively high, and the force on the workpiece is relatively more uniform, especially suitable for pressing large-size powder products, which is in line with the development trend of large-size ITO targets; 2) The density of the product is relatively higher and more uniform; 3) The pressed powder does not need to add any lubricant; 4) The production cost is low and it is suitable for large-scale production.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com