Cold Isostatic Pressing

Categories: Dry bag DIP forming mold

Application: Cold Isostatic Pressing

InquiryMain description:

Cold Isostatic Pressing

Cold Isostatic Pressing

Cold Isostatic Pressing

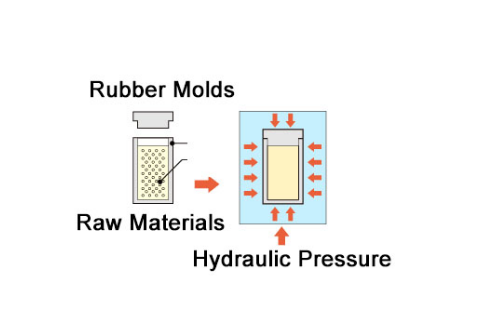

Cold isostatic pressing is a technology to achieve isostatic pressing at room temperature. Usually, rubber or plastic is used as the coating mold material, and liquid or elastomer (plastic, rubber, etc.) is used as the pressure medium. When the pressure medium is liquid, it is called liquid isostatic pressure. Among them, water containing rust inhibitor as the pressure medium is called water isostatic pressure, oil as the pressure medium is called oil isostatic pressure. When the pressure medium is elastomer (such as plastic, rubber, etc.), it is called balanced pressing, soft molding or thick wall molding. Cold isostatic pressure is divided into dry bag isostatic pressure and wet bag isostatic pressure.

Dry bag isostatic pressure

Dry bag method isostatic pressure refers to the rubber bag is first placed in the cylinder, do not take out when working, powder into another plastic bag. Put in a pressurized rubber bag, out of contact with the liquid. Hence the dry bag method. This method can be operated continuously, that is, open the upper cover, load from the hopper, and then cover the upper cover pressure into the receiver, discharge, open the upper cover, through the top rod at the bottom of the billet from the top out.

Wet-bag isostatic pressure

Wet-bag isostatic pressing is to put the powder into the forming mold first, and then put it in the high-pressure cylinder after sealing. During the pressing process, the envelope is fully immersed in the liquid and is in direct contact with the pressure transfer medium. Wet bag method is suitable for experimental research and small batch production, and can be pressed in a high pressure cylinder at the same time more than two different shapes of the parts and the production of large and complex shape of the parts, short production process and low cost.

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com