Polyurethane Cold Isostatic Pressing Bags

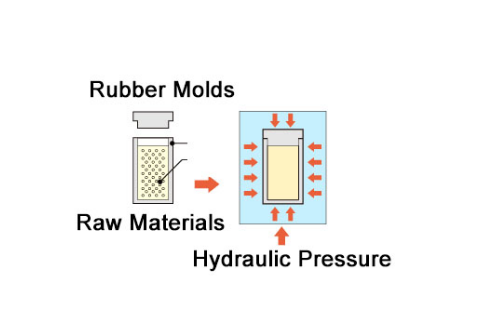

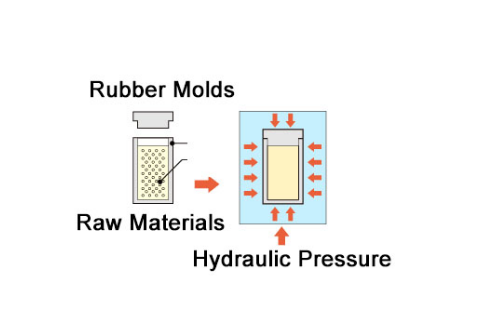

Cold isostatic pressing technology, (Cold Isostatic Pressing, referred to as CIP) is at room temperature, usually with rubber or plastic as the mold material, with liquid as the pressure medium is mainly used for powder material molding, for further sintering, forging or The hot isostatic pressing process provides the green body. The general operating pressure is 100~630MPa.

Cold isostatic molding has wet bag method and dry bag method.

1. Wet bag method isostatic pressure into the powder plastic bag, directly hit the liquid pressure medium, and liquid phase contact, so called wet bag method. This method can arbitrarily change the shape and size of the plastic envelope, the product flexibility is great, suitable for small-scale production. Every time to carry out bagging, unloading operation, production efficiency is not high, can not be continuous large-scale production.

2. Dry bag method isostatic pressure rubber bag is first placed in the cylinder, do not take out when working, powder into another plastic bag, put into the pressure rubber bag, and liquid is not in contact. Hence the thousand-bag method. This method can be operated continuously, that is, open the upper cover, load from the hopper, and then cover the upper cover pressure into the receiver, discharge, open the upper cover, through the top rod at the bottom of the billet from the top out. Short operation cycle, suitable for mass production, but product specifications are limited because the compression plastic die cannot be replaced frequently.

Elastic die and pressure transfer medium

The commonly used materials for preparing elastic molds are: rubber for mold, impregnated latex, polyvinyl chloride, silicone resin, polyurethane, etc. Die design is the key of isostatic pressing, because the precision and compact uniformity of blank size are closely related to die. When the material is loaded into the mold, its edges and corners are not easy to be filled by the material. Vibration charging can be used, or vibration and vacuum pumping can achieve better effect. As the pressure transmission medium of the isostatic pressure system, the liquid that is harmless to human body, has small compressibility, is non-corrosive and compatible with the mold should be selected. Generally, castor oil, emulsion, kerosene and the mixture of kerosene and transformer oil are used.

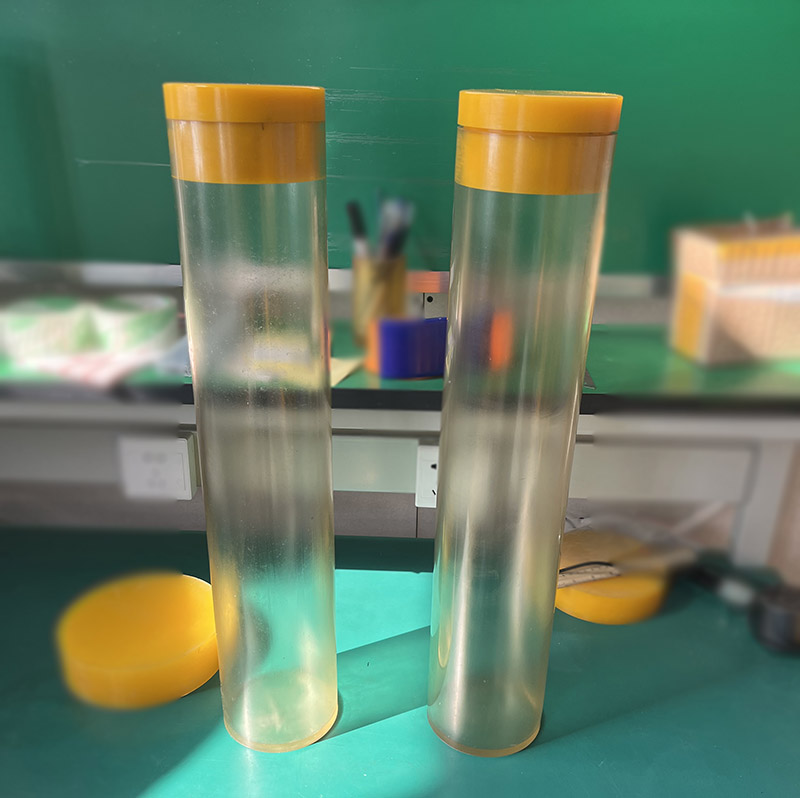

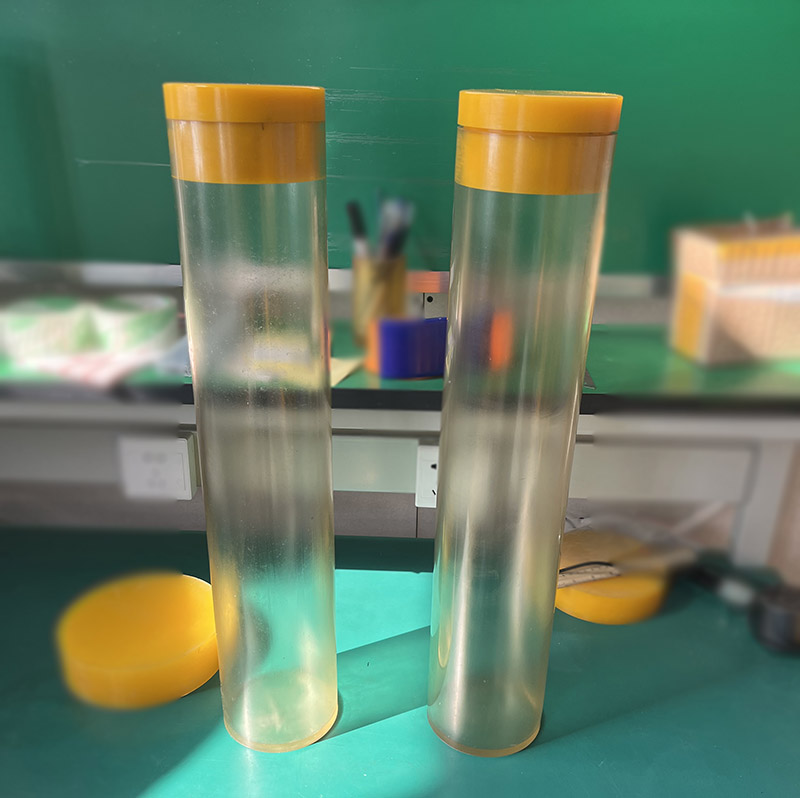

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

Compare to traditional rubber cold isostatic pressing bags, the polyurethane CIP bags have significant advantages. As a new polymer material, polyurethane products feature smooth surface, wearing-resistant, anti-fatigue, low deformation rate. The surface of pressed products with polyurethane bags is much smoother than that pressed with rubber bags, thus it possesses better looks and less postprocessing is required. It’s an ideal tool for powder material forming by press process, which can help a company reduce cost and increase efficiency.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold