Cold Isostatic Pressing- CIP

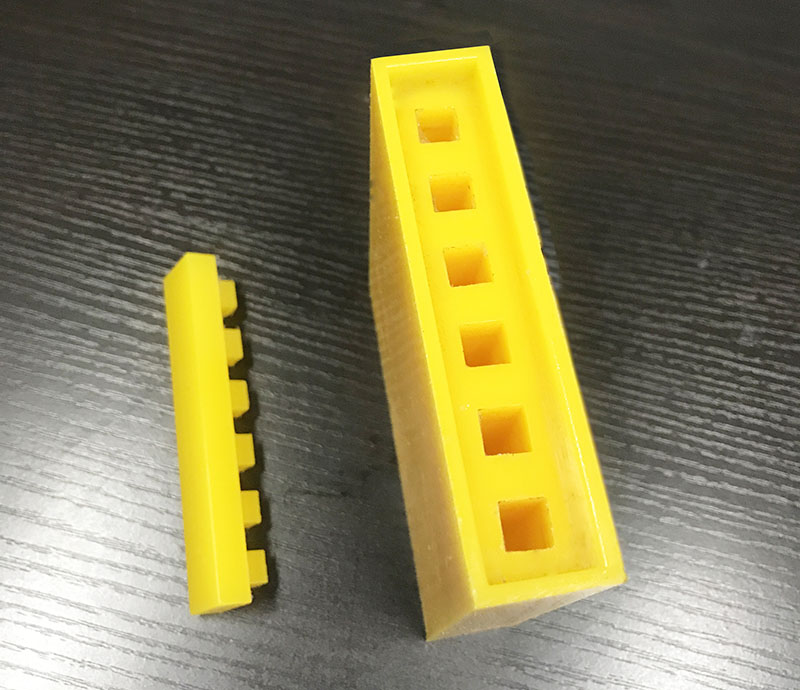

Categories: CIP bags, CIP mold

Application: Cold Isostatic Pressing- CIP

InquiryMain description:

Cold Isostatic Pressing- CIP

Cold Isostatic Pressing- CIP

Cold Isostatic Pressing- CIP

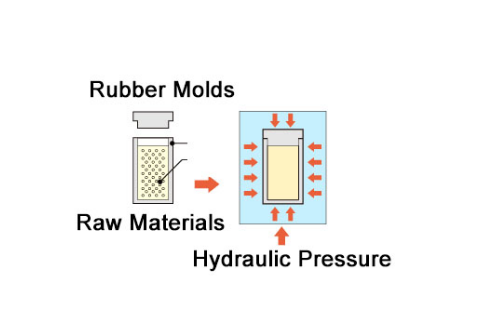

Cold isostatic press is divided into wet bag press and dry bag press according to whether the mold is in contact with the medium. In contact with the medium, the mold is wet, commonly known as wet bag; Does not contact with the medium, the mold is dry, commonly known as dry bag type.

Dry bag isostatic press Cold isostatic press is mainly composed of elastic die, cylinder block (high-pressure vessel), frame, hydraulic system and so on.

(1) Elastic mold. Made of rubber or resin material. The particle size and shape of the material have great influence on the die life. Die design is the key of isostatic pressing, because the precision and compact uniformity of blank size are closely related to die. When the material is loaded into the mold, its edges and corners are not easy to be filled by the material. Vibration charging can be used, or vibration and vacuum pumping can achieve better effect.

(2) cylinder block. A vessel that can withstand high pressure. Generally, there are two structural forms: one is made of two layers of simplified heat charging, the inner cylinder is under pressure, the outer cylinder is under tension, this structure is only suitable for small and medium-sized dry bag isostatic press equipment; The other is to use wire prestressed winding structure, high strength alloy steel with good mechanical properties as the core simplified, and then use high strength steel wire according to the prestressed requirements, wound around the outside of the core tube, the formation of a certain thickness of steel wire layer, so that the core tube to bear great compressive stress. Even under working conditions, without tensile stress or very little tensile stress, the vessel has a very high fatigue life and can be manufactured in large diameter vessels. Both the upper and lower stoppers of the container are active, and when pressurized, the upper and lower stoppers transfer force to the frame.

(3) Framework. There are two types of structure: one is laminated structure, which is composed of medium strength steel plates; The other is the winding frame structure, which consists of two semicircular beams and two columns spliced together and wound with high strength steel wire prestressed. This structure has reasonable force, high fatigue strength and safe and reliable operation.

(4) Hydraulic system. By low pressure pump, high pressure pump and supercharger and all kinds of valves. Start by a large flow of low pressure pump oil supply, reach a certain pressure, and then by the high pressure pump oil supply, such as pressure again high, by the supercharger to improve the pressure of oil. The working medium can be water or oil.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com