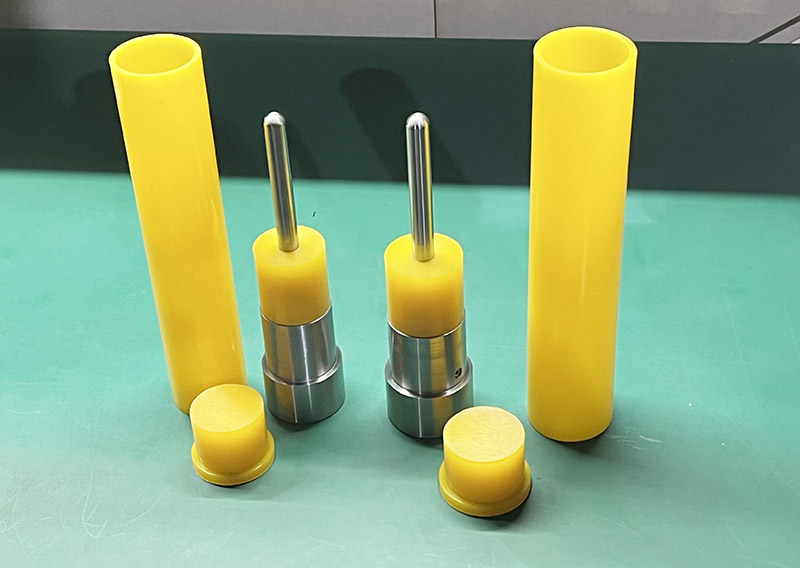

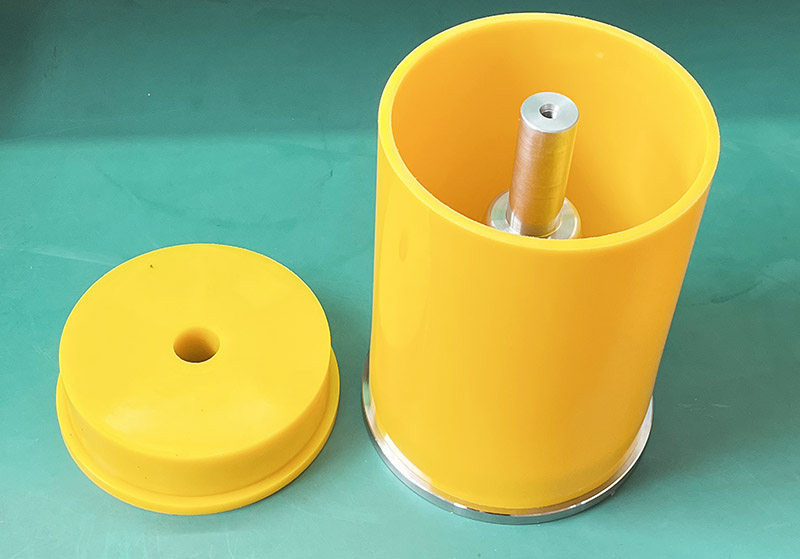

customized CIP bags, isostatic pressing mold

Categories: Powder metallurgy bag mold

Application: customized CIP bags, isostatic pressing mold

Inquiry

thermostability

thermostability

Main description:

Isostatic pressing technology is an advanced ultra-high pressure hydraulic equipment that utilizes the products in a closed high-pressure container to be formed under the state of equal ultra-high pressure in all directions. Isostatic pressing technology is divided into three different types: cold isostatic pressing, warm isostatic pressing and hot isostatic pressing according to the temperature during forming and consolidation.