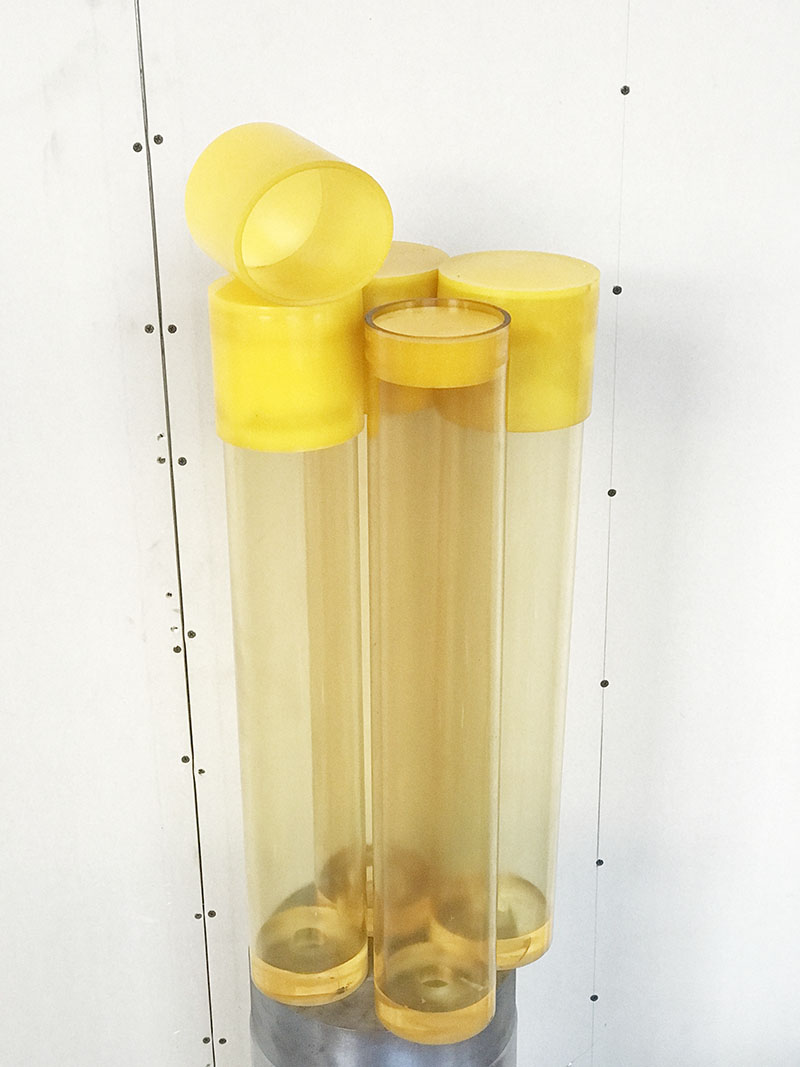

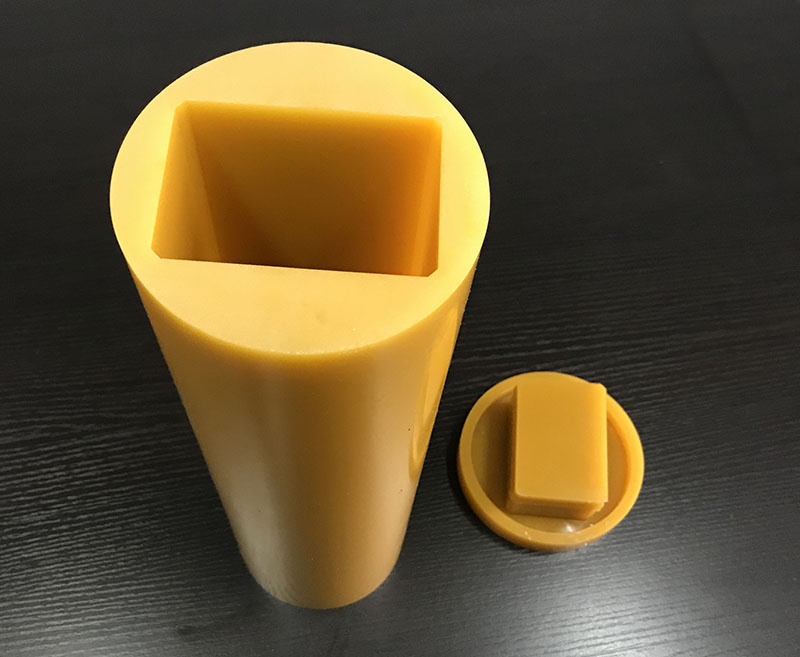

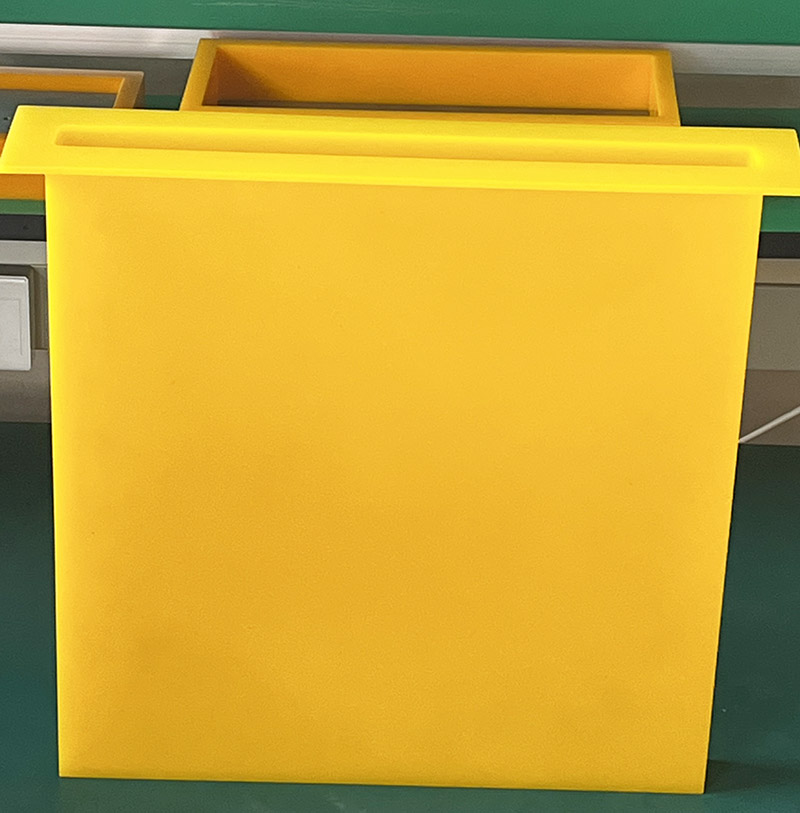

powder materials CIP shaping forming bags, powder isostatic forming bags, powder CIP shaping bags

Categories: Wet bag CIP equipment

Application: powder materials CIP shaping forming bags, powder isostatic forming bags, powder CIP shaping bags

InquiryMain description:

powder materials CIP shaping forming bags, powder isostatic forming bags, powder CIP shaping bags. Common applications for Cold Isostatic Pressing include consolidation of ceramic powders, compressing of graphite, refractories and electrical insulators, and other fine ceramics for dental and medical applications.The technology is expanding into new applications such as pressing of sputtering targets, coatings of valve parts in an engine to minimize wear of the cylinder heads, telecommunications, electronics, aerospace and automotive.