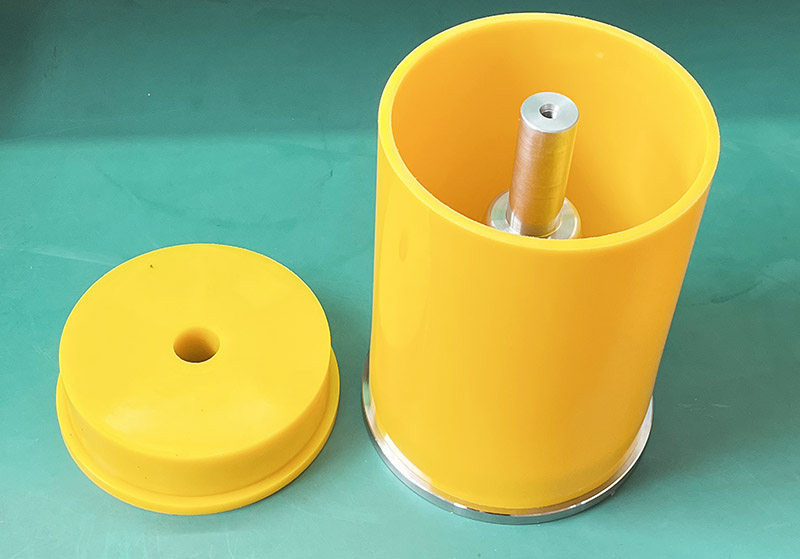

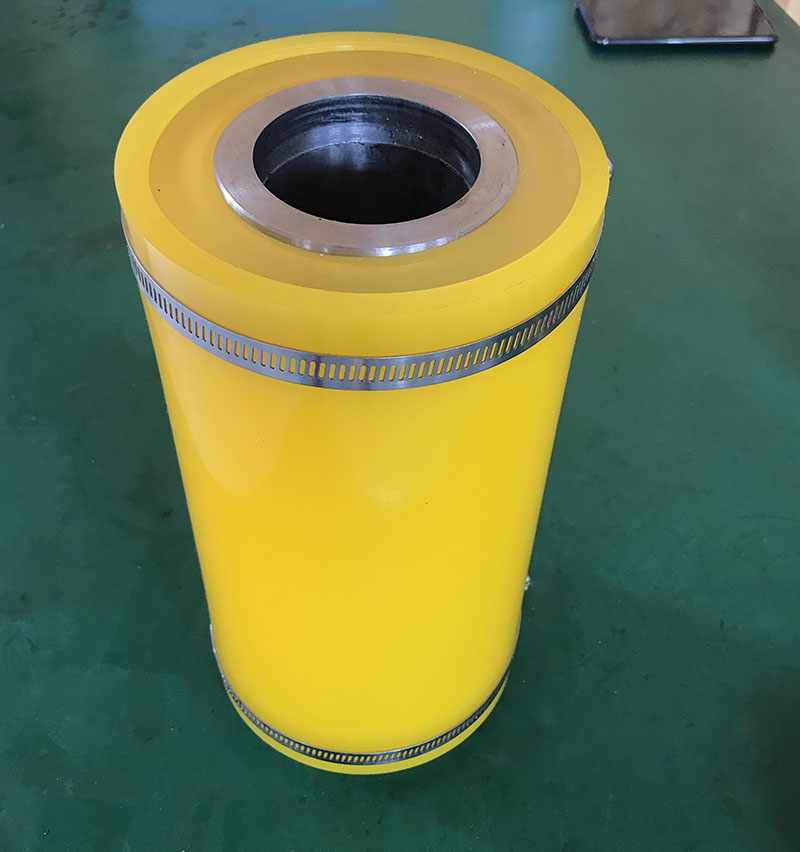

isostatic press bags, isopressing mold, powder forming bags

Categories: Wet bag CIP equipment

Application: isostatic press bags, isopressing mold, powder forming bags

InquiryMain description:

isostatic press bags, isopressing mold, powder forming bags. cold isostatic pressing of coarse grained alumina refractories applying either a cyclic pressure increase or a cycling at maximum pressure. Additionally the effects of the maximum pressure and the particle size distribution on physical, mechanical and thermomechanical properties were analyzed. The cyclic pressure increase resulted in a slightly higher apparent density and lower apparent porosity. A cycling at maximum pressure decreased the median pore size to some extent. Remarkably, an optimized particle size distribution resulted in a lower apparent porosity, lower median pore size and in a higher Young's modulus before and after thermal shock together with a slightly lower relative decrease of the Young's modulus.

The cyclic pressure increase resulted in a slightly higher apparent density and lower apparent porosity. A cycling at maximum pressure decreased the median pore size to some extent. Remarkably, an optimized particle size distribution resulted in a lower apparent porosity, lower median pore size and in a higher Young's modulus before and after thermal shock together with a slightly lower relative decrease of the Young's modulus.

The cyclic pressure increase resulted in a slightly higher apparent density and lower apparent porosity. A cycling at maximum pressure decreased the median pore size to some extent. Remarkably, an optimized particle size distribution resulted in a lower apparent porosity, lower median pore size and in a higher Young's modulus before and after thermal shock together with a slightly lower relative decrease of the Young's modulus.