What is isostatic pressure?

Isostatic pressing is a powder metallurgy (PM) forming process that applies equal pressure in all directions on a powder compact thus achieving maximum uniformity of density and microstructure without the geometrical limitations of uniaxial pressing. Isostatic pressing is performed "cold" or "hot.".

WHAT IS HOT ISOSTATIC PRESSING ?

Hot Isostatic Pressing (HIP) is a process to densify powders or cast and sintered parts in a furnace at high pressure (100-200 MPa) and at temperatures from 900 to 1250°C for example for steels and superalloys. The gas pressure acts uniformly in all directions to provide isostropic properties and 100% densification.

WHAT IS COLD ISOSTATIC PRESSING?

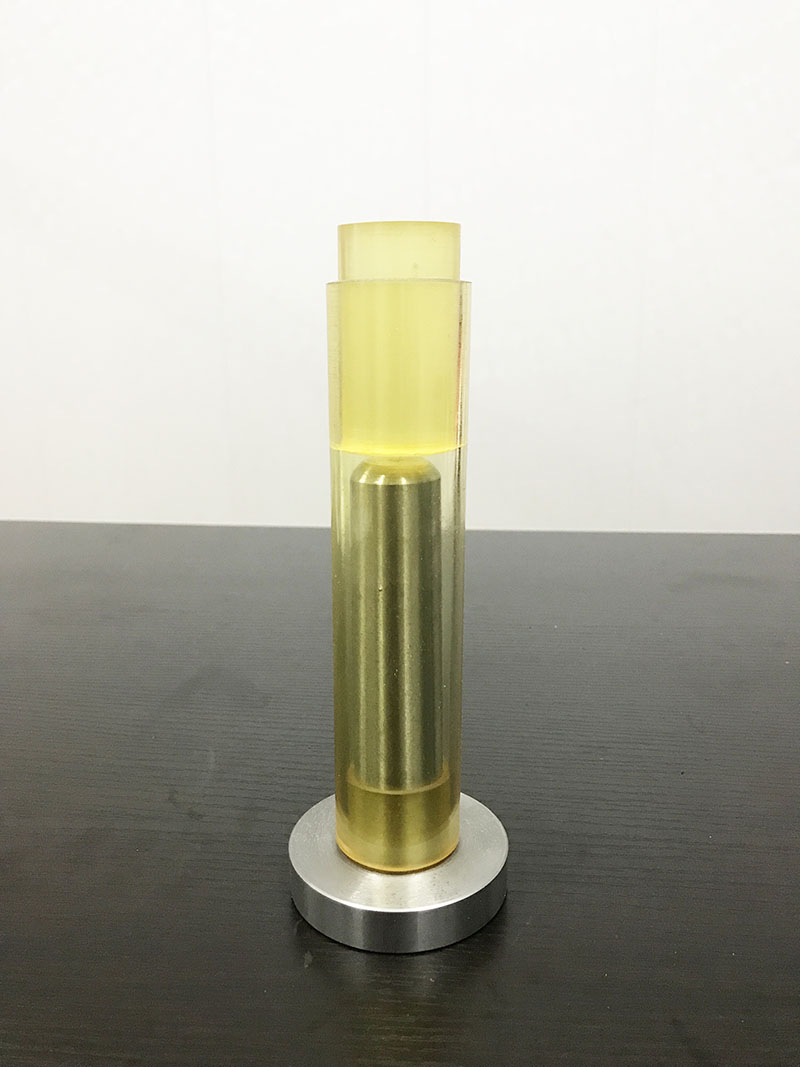

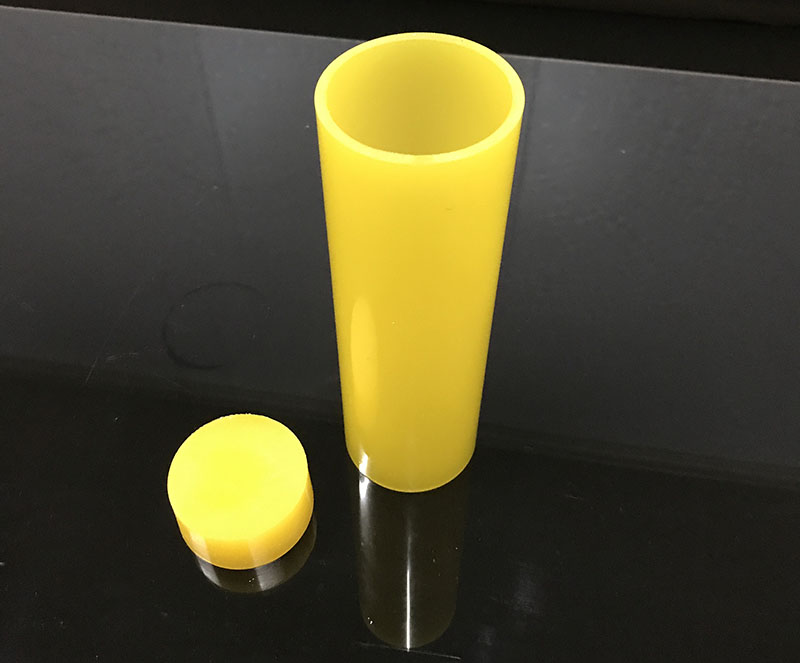

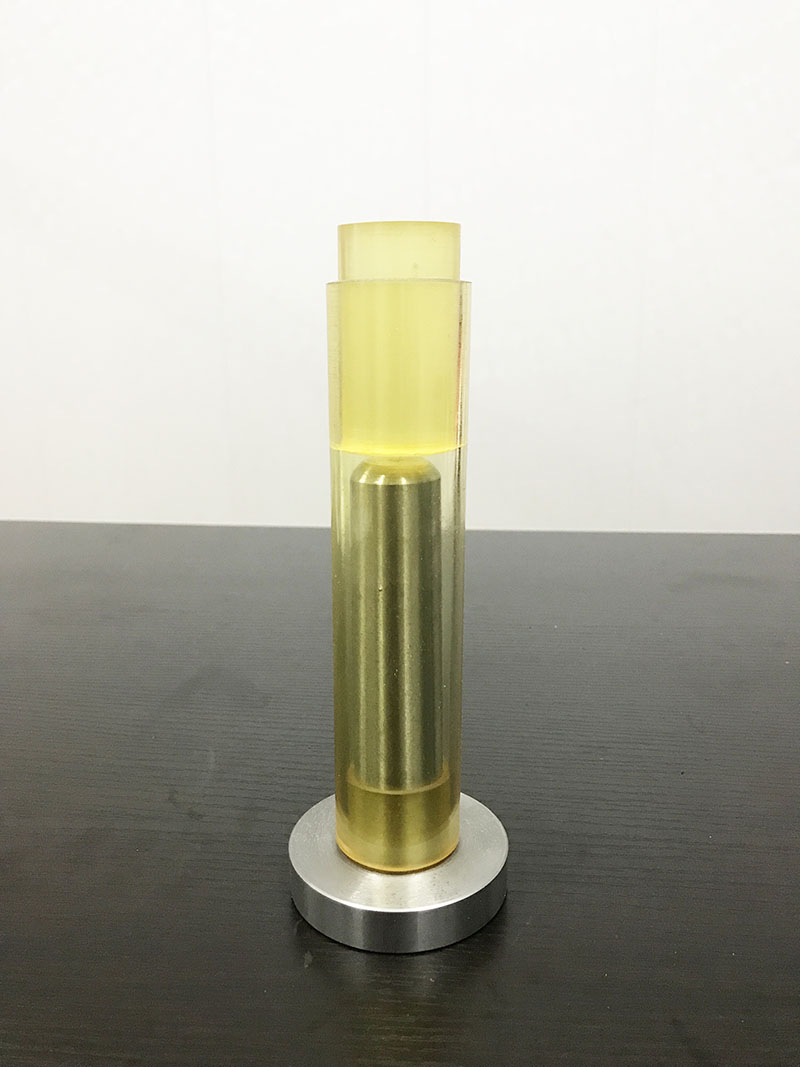

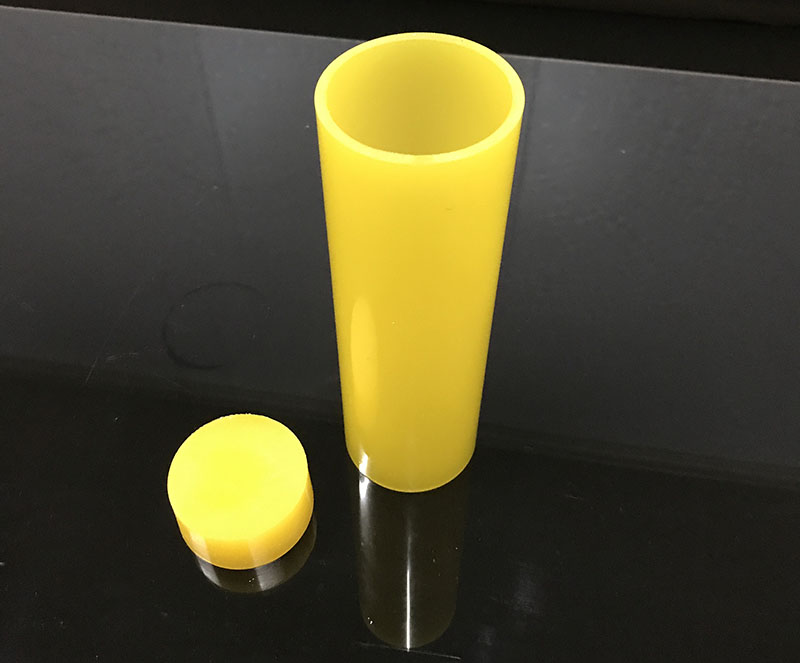

CIP, Cold Isostatic Pressing, is one of material processing methods. It makes use of the principle "A change in the pressure of an enclosed incompressible fluid is conveyed undiminished to every part of the fluid and to the surface of its container." proposed by the French scientist Blaise Pascal.

What is the difference between hot isostatic pressing and cold isostatic pressing?

Isostatic pressing is performed "cold" or "hot." Cold isostatic pressing (CIP) is used to compact green parts at ambient temperatures, while hot isostatic pressing (HIP) is used to fully consolidate parts at elevated temperatures by solid-state diffusion.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com