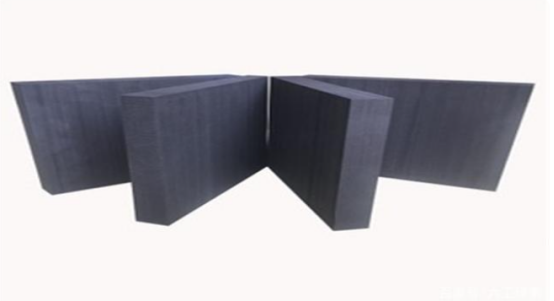

Isostatic Graphite

Isostatic graphite is a new product developed internationally in the past 50 years and is closely related to today's high technology. Not only has great achievements in civilian use, but also occupies an important position in national defense. It is a new type of material and attracts attention. It is an irreplaceable material for the manufacture of single crystal furnaces, metal continuous casting graphite molds, and graphite electrodes for electrical discharge machining.

There are three main methods of forming graphite products:

1. Hot extrusion molding: such as the production of graphite electrodes for steelmaking.

2. Compression molding: used for aluminum carbon and electric carbon products.

3. Isostatic pressing: The raw materials of isostatic pressing graphite are pressed in all directions, and the carbon particles are always in a disordered state, so that the product has no or little performance difference, and the performance ratio in the direction is not greater than 1.1. Known as: "Isotropic".

Isostatic graphite has a broad market, and the main uses of isostatic graphite are:

1. Heater for Czochralski monocrystalline silicon thermal field and polycrystalline silicon ingot furnace:

In the thermal field of Czochralski monocrystalline silicon, the components of isostatic pressing graphite include crucibles, heaters, electrodes, heat shielding plates, seed crystal holders, bases for rotating crucibles, various circular plates, heat reflecting plates, etc. 30 kinds. Among them, 80% of the isostatic graphite is used in the manufacture of crucibles and heaters. In the manufacturing process of polycrystalline silicon wafers for solar cells, polycrystalline silicon fragments are first melted and cast into polycrystalline silicon ingots. Among them, the heater of the ingot furnace needs to be made of isostatic graphite.

2. Atomic energy industry:

In nuclear fission reactors (high temperature gas-cooled reactors), graphite is a moderator of neutrons and an excellent reflector. A graphite material with good thermal conductivity and high mechanical strength is used as the first wall material facing the plasma.

3. Discharge electrode:

Electric discharge machining, which mainly uses graphite or copper as electrodes, is widely used in metal molds and other processing fields.

4. Graphite mold for continuous casting of non-ferrous metals:

Because the isostatic pressing graphite material has good properties in terms of heat conduction, thermal stability, self-lubrication, anti-wetting and chemical inertness, it becomes an irreplaceable material for making crystallizers.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com