Process flow and Application of Powder Metallurgy

I. Basic process flow of powder metallurgy process

Step 1: Preparation of raw materials into metal powder

A step in the preparation of raw materials into metal powders by oxide reduction and mechanical methods.

Step 2: Make the Bread

According to different product requirements, use wet or dry or semi-dry to mix the powder evenly in a certain equal proportion to make green powder, and the proportion of the powder must be well controlled.

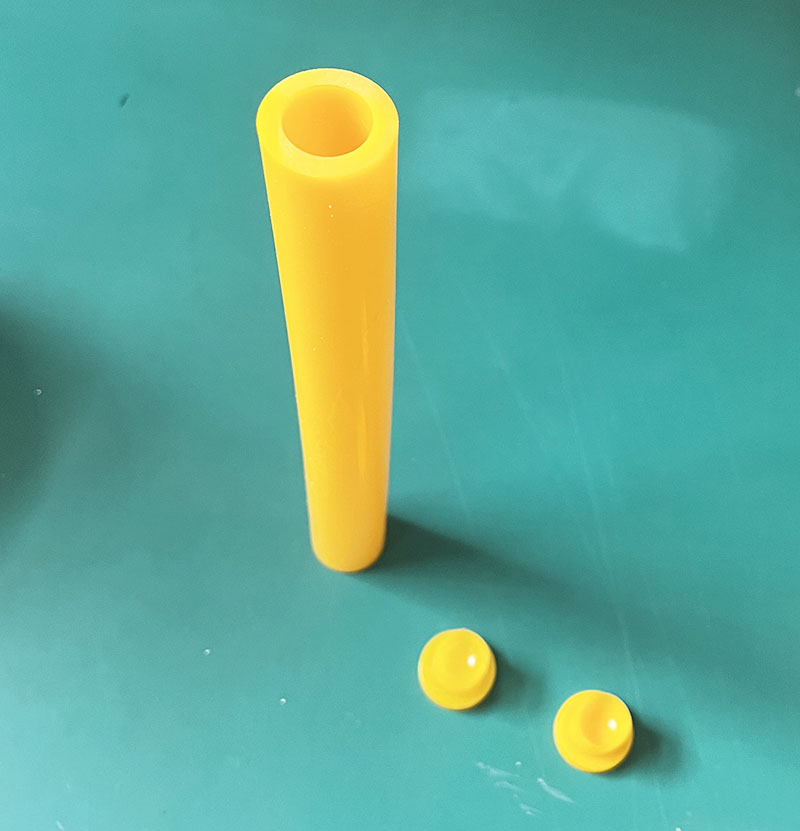

Step 3: Forming of the mold

The mixed green powder is put into the corresponding forming mold of powder metallurgy, and is formed into the desired shape by pressure forming or no pressure forming.

Step 4: Sintering of powder metallurgy model products

The formed model can be sintered by multi-component sintering or unit sintering to form the required physical and mechanical properties of the final product. The powder metallurgy sintering process is the most important step in the entire process, and it is also the decisive process for product performance.

Step 5: Sintering Subsequent Details

For products with high product precision requirements, after the sintering process, follow-up finishing, oil immersion, electroplating, or a small amount of machining, heat treatment and other details are required to make the product more stable and harder.

II. In which fields is the powder metallurgy process applied?

1: Automotive field

Powder metallurgy process parts for gears, engine rotors, tailgates, wipers, etc. in the automotive field.

2: The field of digital electronic appliances

Powder metallurgy process application of spare parts such as smart phones, notebook computers, smart wearables, home appliances, etc.

3: The field of hardware tools

Locks, lock tongues, power tools, and hardware tool parts all use powder metallurgy molding technology.

4: Communication field

The gear box, antenna and other spare parts of base station communication all adopt powder metallurgy process.

5: Medical device field

Medical devices have relatively high requirements for spare parts, and the powder metallurgy net forming technology is very suitable for the application of medical device spare parts, with higher precision and cleaner products.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com