CIP processing type

According to the relationship between powder filled mold and pressure medium, CIP forming methods are divided into wet bag method and dry bag method.

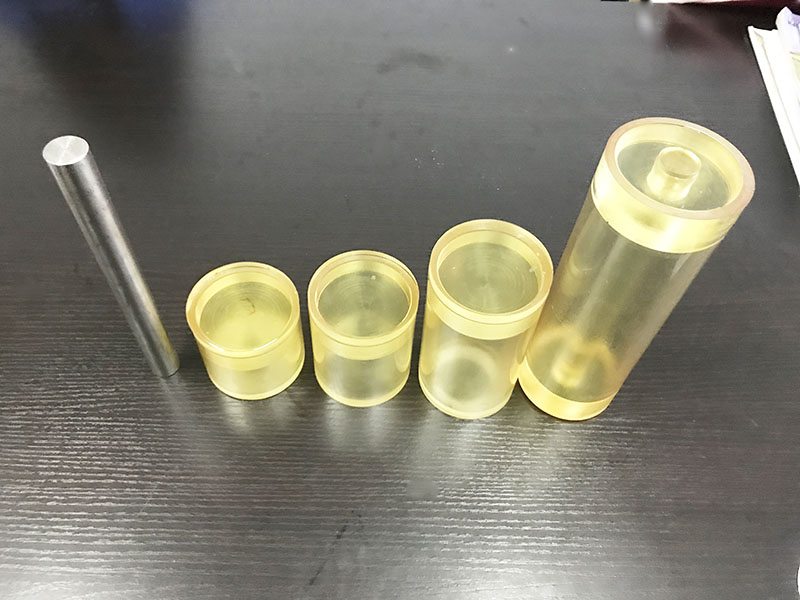

Wet bag method

In the wet bag process, the powder is filled in the forming mould and sealed outside the high-pressure vessel before being directly immersed in the pressure medium. Then, isostatic pressure is applied on the surface of the die to compress the powder. This method is suitable for small batch production and trial production of various complex shapes or large products.

There are two types of structure:

1.The external pressurized type , which pressurizes the pressure medium into the pressure vessel from the outside;

2.The piston direct pressurized type, which pressurizes the pressure medium sealed in the pressure vessel directly, and installs the piston instead of the top cover.

Dry bag method

The dry bag method is to transfer the pressure through the pressed rubber mold in the high-pressure vessel and fill the powder in the formed rubber mold. The method is labor-saving and highly automatic, and is suitable for the production of simple and limited products.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com