Selection of isostatic pressing die structure and isostatic pressing die sleeve material

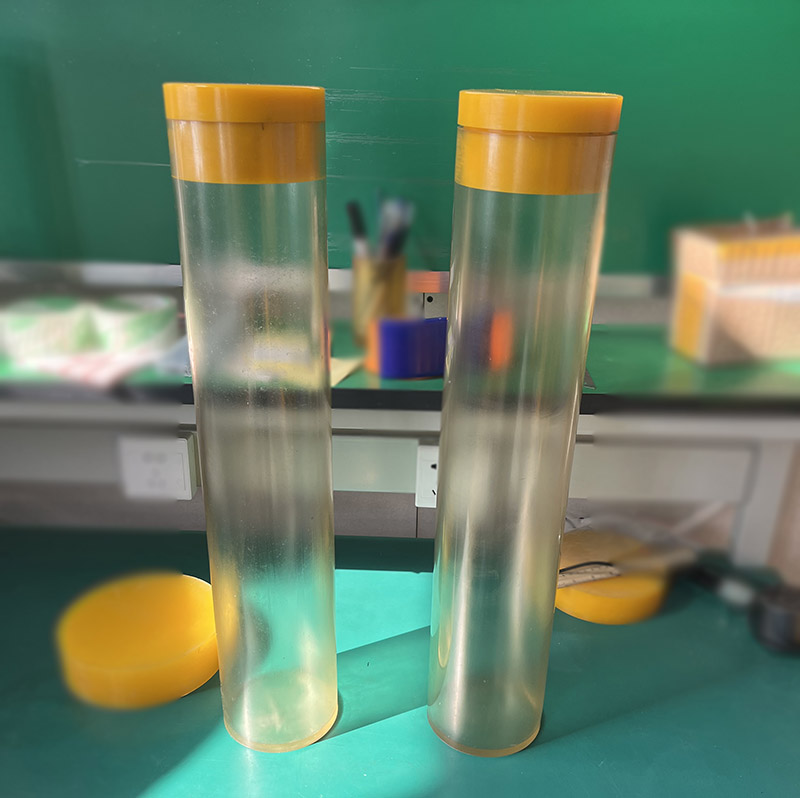

The isostatic pressing mold has a crucial influence on the molding effect of CIP cold, etc. The structure of the isostatic pressing mold determines the molding effect, and the structure of the mold also affects the troublesome effect and production efficiency. The materials of isostatic pressing molds include polyurethane, rubber and silicone, etc. After comparative experiments, isostatic pressing molds made of polyurethane have detailed advantages in all aspects, and are more and more selected. In isostatic pressing, the prototype to be pressed is placed in a high-pressure container, the pressure is uniformly transmitted through the liquid pressure transmission medium, and the various parts are pressurized from all directions, so that the workpiece is formed and the desired effect is achieved. In this pressing process, the workpiece needs to be isolated from the pressure transmission medium, and cannot be in contact with the pressure transmission medium (hydraulic oil) to cause mutual contamination. This requires isostatic pressure molds (sleeves) that can meet hydraulic work.

Traditional isostatic pressing molds include isostatic pressing rubber molds, silicone molds and steel molds, and there are many problems in practical applications. As a new type of polymer material, polyurethane has many advantages such as wide range of hardness, high strength, wide adjustable range of performance, wear resistance, tear resistance, oil resistance, chemical resistance, oxidation resistance and so on. The deformation of the elastic mold under the pressure of the liquid medium is transmitted to the powder in the mold. The friction between the powder and the mold wall is small, the force of the blank is uniform, and the density distribution is uniform, and the pre-pressed blank is encapsulated. In an elastic rubber mold, it is sealed and put into a high-pressure cylinder, and the green body is compressed and formed by liquid transfer. The mold is used for the molding of ceramic materials, tungsten and molybdenum materials, graphite materials, fire-resistant materials, and alloy powders.

As a molding process, isostatic pressing technology has the following characteristics compared with conventional molding technology:

a. The product density of isostatic pressing is high, generally 5-15 higher than that of one-way and two-way pressing. The relative density of HIP products can reach 99.8% to 99.09%.

b. The density of the compact is uniform. In compression molding, whether it is unidirectional or bidirectional pressing, there will be uneven density distribution of the green compact. This density change can often reach more than 10% when pressing complex-shaped products. This is due to the frictional resistance between the powder and the steel die. An isostatic fluid medium transmits pressure, equal in all directions. The packing and the powder are compressed roughly the same, the powder and the packing have no relative motion, the frictional resistance between them is very small, and the pressure only decreases slightly. Therefore, the green body density can be considered to be uniform.

c-because the density is uniform. Therefore, the length-diameter ratio of production is not limited, which is conducive to the production of rod-shaped, tubular and slender products.

d. The isostatic pressing process generally does not need to add lubricant to the powder, which not only reduces the pollution to the product, but also simplifies the manufacturing process.

If you are interested in the Polyurethane CIP bags, you can contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com