Cold Isostatic Pressing Technology for Stainless Steel Filter

Corrosion resistant and easy to clean sintered stainless steel filter is made of irregular stainless steel powder processing, isostatic pressing, molding, extrusion molding through high temperature sintering. With special technology and strict production process, it has the advantages of high mechanical strength, high temperature resistance, corrosion resistance, uniform aperture, good air permeability, easy to clean, reusable, weldable, machined and so on.

It has good permeability filtration performance and high filtration accuracy, and has certain strength and toughness, and can be used at a high temperature of 300℃. Mainly used in petroleum, chemical, environmental protection, metallurgy and other basic industries, as filter materials, porous electrode materials, sound absorption materials, damping materials, divergent cooling materials, catalysts and catalytic materials, antifreeze and buffer materials.

The advantages of cold isostatic forming method are: (1) it can press complex shapes of parts that can not be pressed by molding. For example, aircraft hydraulic titanium joints, ball valve titanium balls used in seawater, Ti-6AI-4V lens seats and so on. Thus, the processing allowance can be greatly reduced and expensive metals can be saved. (2) Can press the length to diameter ratio of large pipe fittings, threads or section by section reducer rod. Commonly used to press stainless steel, titanium filters. (3) Due to the isotropic pressure of the powder, a compact with high density and uniform distribution and high strength can be obtained. In pressing the hard powder, high quality compact is obtained at low pressure without adding forming additives, which can become the early process of the subsequent hot densification chemical process (hot rolling, hot extrusion, etc.). (4) can press various parts with different properties of laminating parts, parts with inserts, etc.

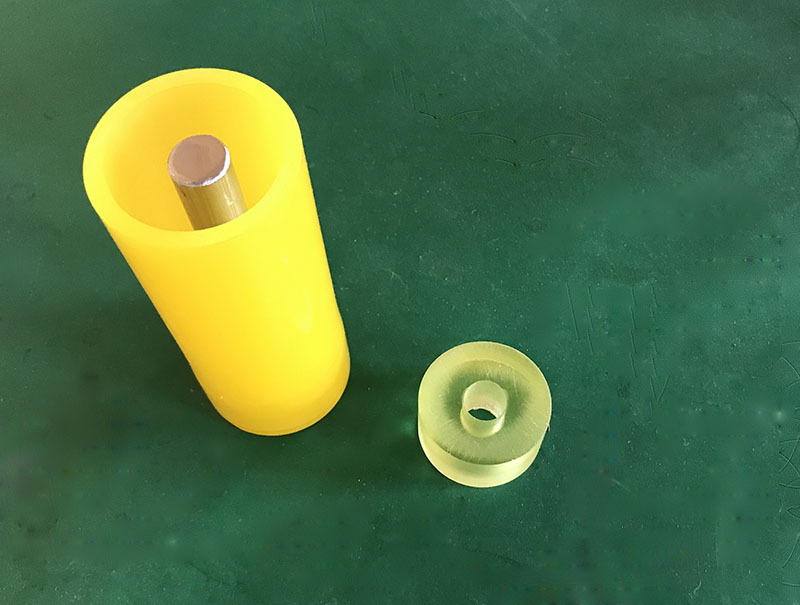

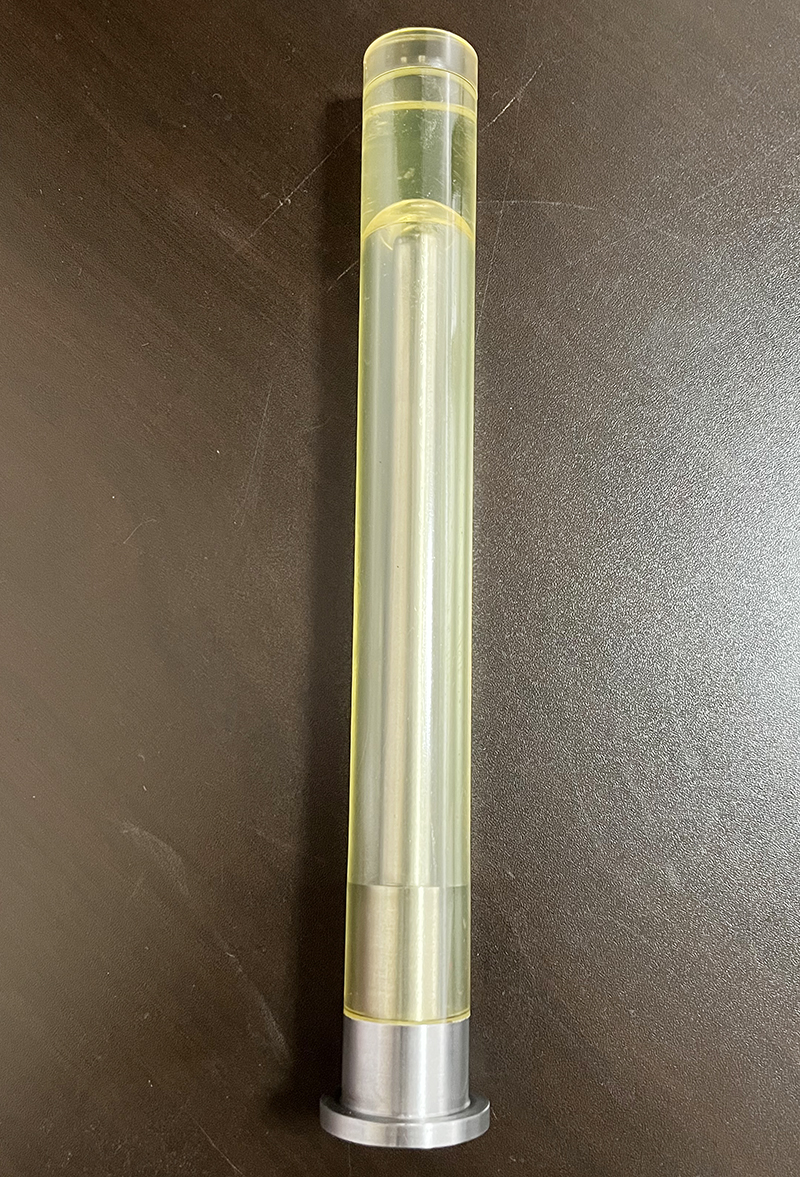

A sample of CIP molds

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com