The Advantages of Polyurethane Isostatic Pressing Molds

Categories: Industry news

Application: The Advantages of Polyurethane Isostatic Pressing Molds

InquiryMain description:

The Advantages of Polyurethane Isostatic Pressing Molds

The Advantages of Polyurethane Isostatic Pressing Molds

The Advantages of Polyurethane Isostatic Pressing Molds

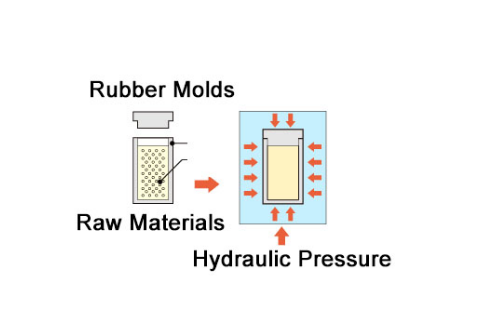

The isostatic pressing method is a method in which equal pressure is applied to the mud in all directions for molding. The commonly used stress transmission medium is liquid, such as oil, water or glycerin. Because the compressibility of brake fluid or anhydrous glycerin is very small, almost all the pressure can be transmitted to the elastic mold, so these two liquids are often used as pressure transmission medium.

Polyurethane isostatic pressing molds have the following advantages:

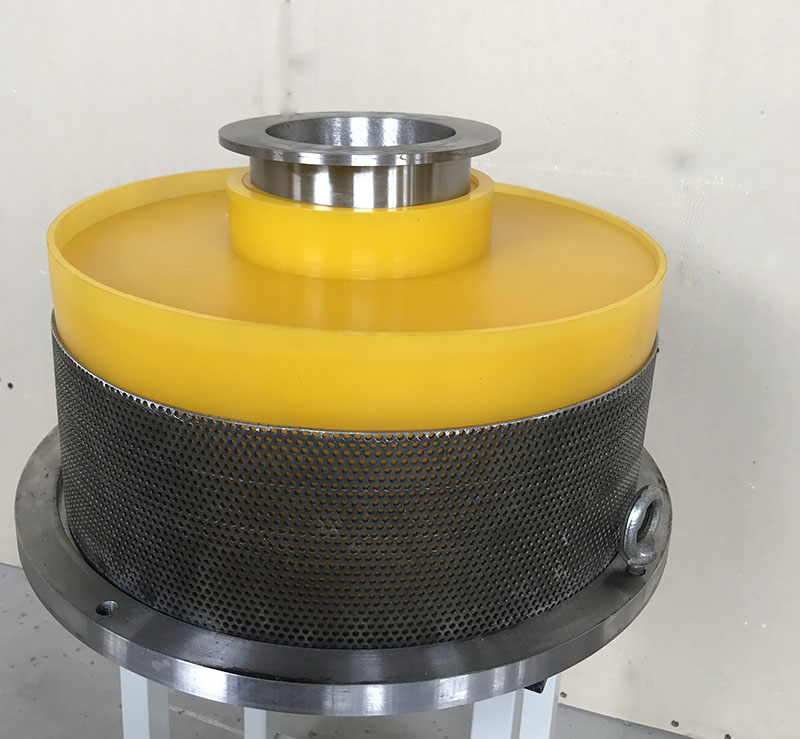

1. Polyurethane isostatic pressing has a longer service life. Compared with rubber, polyurethane has better pressure resistance, quick rebound after pressure, small deformation, and long-term use without reducing accuracy. Moreover, the surface of the isostatic rubber mold is prone to oxidation and stickiness after being used for a long time, while the polyurethane material has anti-oxidation ability, and the performance of the mold will not decrease after long-term use or storage.

2. The surface of the polyurethane PU material mold is smoother, and the surface of the pressed finished product is also smooth, reducing post-processing, improving efficiency and reducing costs.

3. The isostatic pressing mold of polyurethane PU material has higher precision. Polyurethane molds are made by casting, with higher precision and more uniform material, and the advantages are more obvious when pressing high-precision products. 4. The demoulding of polyurethane isostatic mold is easy. Polyurethane has good rebound, non-stick material, quick demoulding after pressing, less post-processing and high efficiency. Adjust the mold hardness according to the shape of the product.

5. The scope of mold application is wider. Polyurethane materials have a wide range of hardness, and can be made into isostatic pressing molds with different hardness according to different equipment or pressing processes. For example, when pressing large-sized workpieces, use polyurethane materials with relatively high hardness to make rigid molds, which have good support when loading materials, and the molds will not deform; when pressing some special-shaped parts, use polyurethane soft molds with low hardness , easy to demould after pressing, easy to use, these characteristics are not satisfied by the isostatic rubber mold. 6. Small deformation and high yield. Polyurethane isostatic mold is poured from liquid polyurethane prepolymer, the material is more uniform, and the pressure transmission is more uniform during the pressing process.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com