Isostatic Pressing Molds for Isostatic Crucible

What is the basis of the isostatic crucible forming process?

The carbon paste or pressed powder loaded into the mold is directly pressed in a high-pressure container to form a green body, the operating procedure and process rules of hydroisostatic pressing. Isostatic pressing is often used to produce fine-grained, homogeneous high-density graphite or isotropic graphite. There are two types of isostatic pressing, that is, liquid isostatic pressing with liquid as the pressure medium and gas isostatic pressing with gas as the pressure medium. Gas isostatic pressing is generally carried out in a heated state (mainly used in the powder metallurgy industry), and the production of carbon products is mainly formed by liquid isostatic pressing.

A Brief History As early as the early 20th century, when the traditional mechanical pressing process was used to produce refractory metal tungsten, molybdenum bars and other products, difficulties were encountered, such as cracks, delamination, and low mechanical strength of the products. Pressing technology to form tungsten, molybdenum and other metal strips solved these problems. In 1913, Madden (HD. Madden) applied for the patent right to produce tungsten and molybdenum strips by cold isostatic pressing technology. In the ceramic industry, Mcneil (Mcneil) succeeded in molding ceramic hollow products by isostatic pressing in 1915. After 1960, isostatic pressing technology was popularized and applied in nuclear energy material production, powder metallurgy and other fields. China has carried out research on isostatic pressing forming technology since 1960. With the development of special refractory materials, isostatic pressing forming technology has entered China's refractory material industry. high l. 5-2.0m, rated pressure of 300MPa cold isostatic press forming long nozzles for continuous casting steel, submerged nozzles, integral stoppers and other products. In the early 1980s, isostatic pressing technology was introduced into the production of carbon products, and successively developed and produced high-density graphite blocks for EDM with ultra-fine particle structure, graphite blocks for molds for continuous steel casting, and more high-density special graphite products. , By the end of the 20th century, China's carbon factory already had a number of cold isostatic pressing equipment of different specifications with liquid as the pressure medium.

Isostatic Crucible

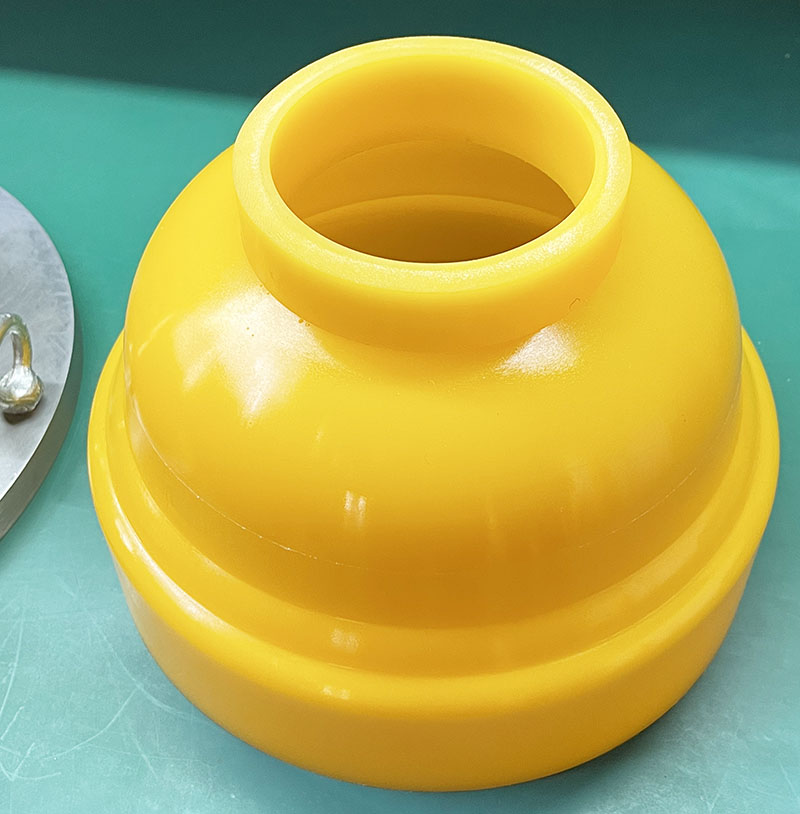

Working principle The basic principle of liquid isostatic pressing is to follow Pascal's law in fluid mechanics, that is, in a closed container filled with liquid, the pressure applied to any point in the fluid must be transmitted to any point in the container with the same value. parts. The isostatic pressing process is to put the powder material to be pressed into an elastic mold, and tie the mold mouth tightly. The mold with material is placed in a high-pressure container, and then the entrance of the high-pressure container is tightly sealed. The pressurized medium is generally transformer oil. Use an ultra-high pressure pump to inject transformer oil into the high-pressure container to pressurize the mold evenly. The pressure in the container can rise to 100-600MPa. After a certain period of time, gradually reduce the pressure, discharge the medium, and open the container inlet. Unload the mold, obtain the formed green body from the mold, and then further heat treatment (roasting, graphitization) and mechanical processing to obtain the desired finished product.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold