Isostatic Pressing Hard Alloy Mold

Categories: Industry news

Application: Isostatic Pressing Hard Alloy Mold

InquiryMain description:

Isostatic Pressing Hard Alloy Mold

Isostatic Pressing Hard Alloy Mold

Isostatic Pressing Hard Alloy Mold

Hard alloy rod is hard alloy round rod, also called tungsten steel rod, in short, tungsten steel round rod or hard alloy round rod. Hard alloy is a composite material made of refractory metal compound (hard phase) and bonded metal (bonded phase) produced by powder metallurgy. Hard alloy is also known as tungsten steel.

There are two forming methods for the production of cemented carbide round rods: one is extrusion forming, which is a suitable way to produce long rods. It can be truncated to any length desired by the user during the extrusion process. However, the overall length should not exceed 350mm. The other is molding, which is a suitable way to produce short bar material. As the name suggests, the hard alloy powder is pressed into shape with a mold.

The raw materials are wet-ground, dried, mixed, and then dried for stress relief after molding or extrusion. Finally, the final alloy blank is formed by degreasing sintering

The disadvantage of round bar extrusion production is that the production cycle is long. Extrusion of small diameter round bar below 3mm, pinching both ends will waste a certain amount of material. The longer the length of the carbide small diameter round bar, the worse the straightness of the blank. Of course, straightness and roundness can be improved by cylindrical grinding in the later period.

The other is molding, which is the production of short bar material. As the name implies, the hard alloy powder is pressed into shape by the mold. The advantage of this kind of cemented carbide bar forming method: it can be formed at one time and reduce waste products. Simplify the line cutting process, save the dry material cycle of extrusion. The above shortened time can save 7-10 days for customers.

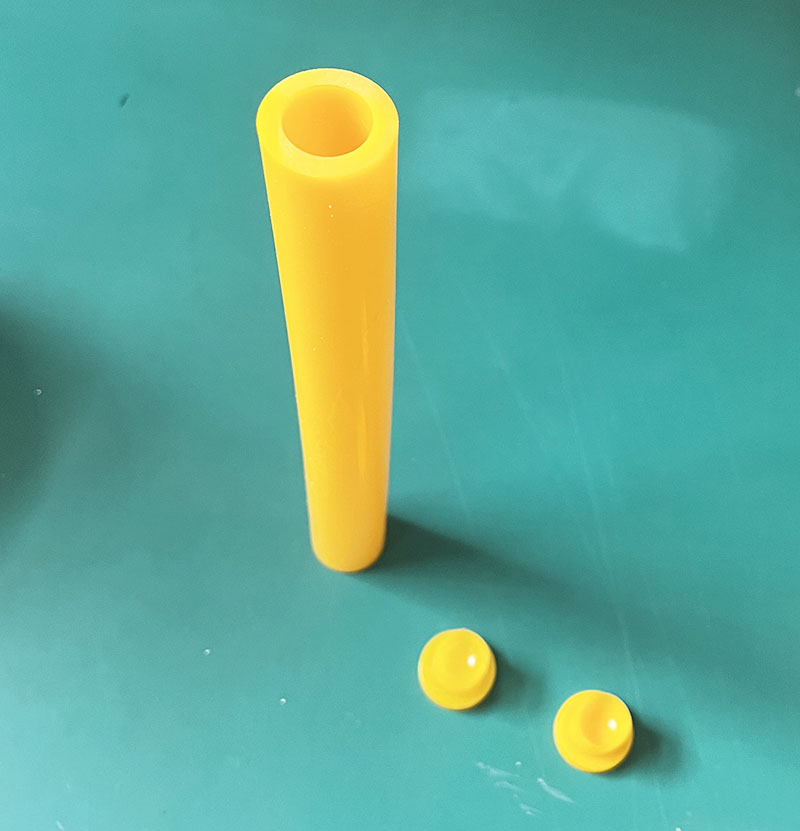

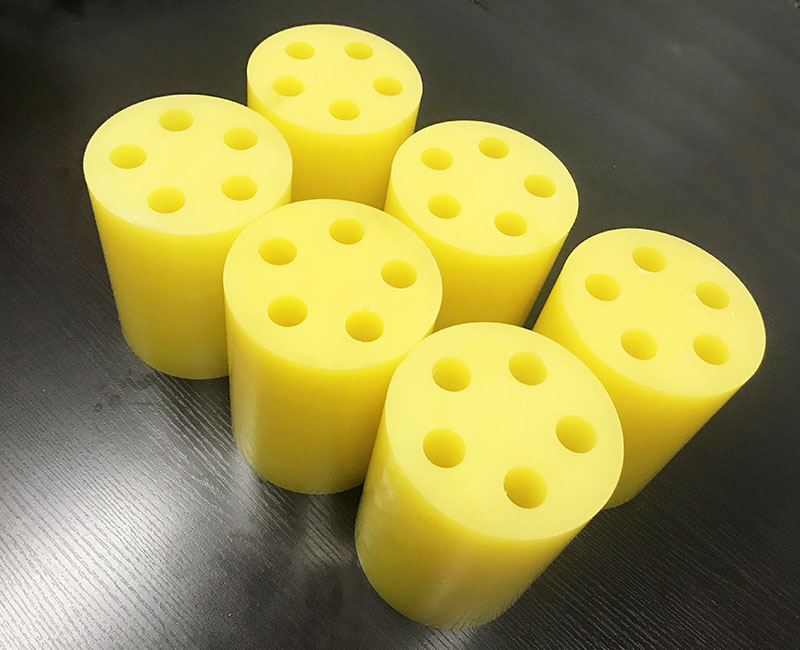

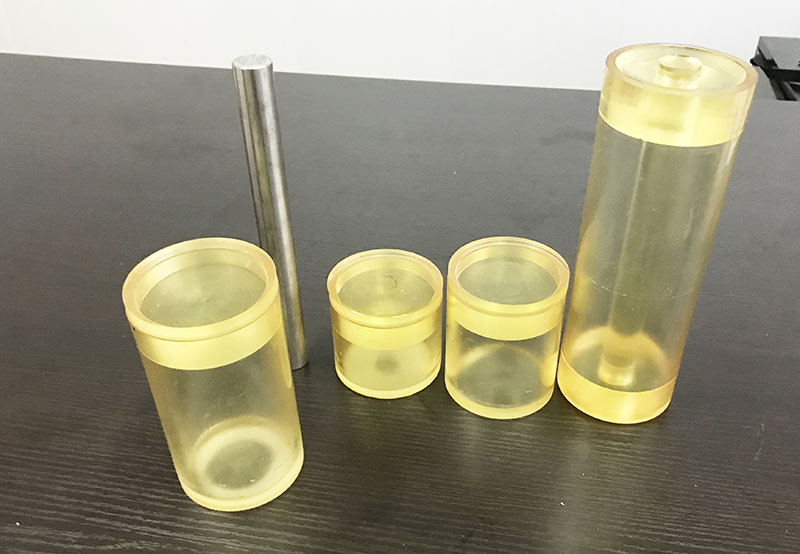

Strictly speaking, isostatic pressing is also a form of molding. Isostatic pressing is the most ideal forming method for producing large and long cemented carbide round rods. Through the upper and lower piston seal, the pressure pump will inject the liquid medium into the high pressure cylinder and the pressure rubber, through the pressure rubber will transfer the pressure to the hard alloy powder compression molding.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com