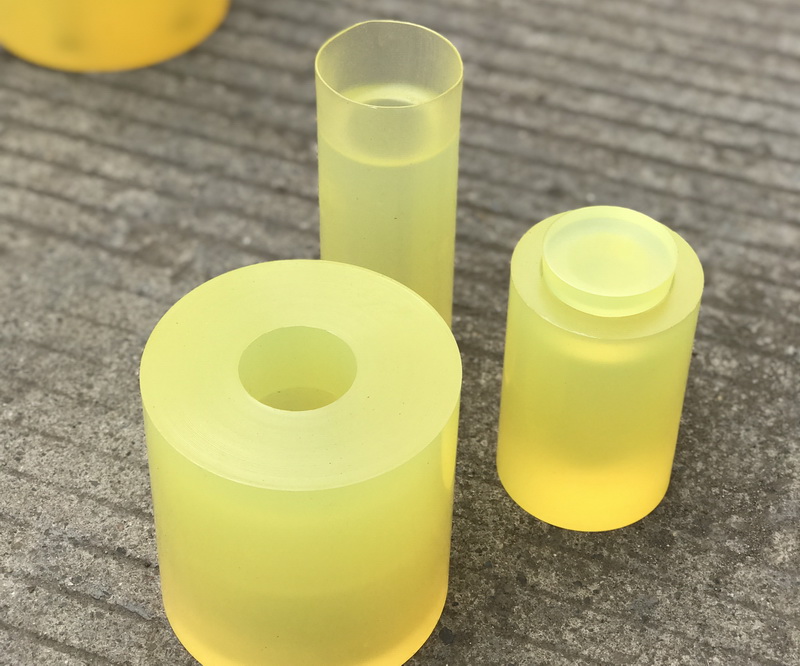

Polyurethane Isostatic Pressing Mold

Rubber isostatic pressing mold, compared with polyurethane isostatic pressing mold rubber sleeve, mainly focuses on the following aspects: mold strength, molding effect, service life, convenience of demoulding, wide application and so on.

1. Polyurethane isostatic mold has higher strength, better elasticity and tear resistance.

2. Polyurethane isostatic pressure bag is non-stick and easy to release from the mold.

3. Polyurethane isostatic pressure bag has stronger anti-aging ability and can be placed for a long time.

4. The polyurethane isostatic pressing mold has a large hardness adjustment range, which can meet the isostatic pressing molding of different materials and different processes.

In the finite element analysis of the stress field of the hot isostatic pressing composite connection of shell members, the effect of the sheath also needs to be considered. If the jacket is incorporated into the workpiece for analysis together, a contact analysis between the jacket and the workpiece must be performed. Contact analysis belongs to the analysis of highly nonlinear boundary conditions, which will not only increase the computational workload, but also many contact analysis parameters (such as contact tolerance, separation force, etc.) are difficult to determine experimentally. In the process of contact analysis, the calculation result is often incorrect or the calculation process is difficult to converge due to the inaccuracy of the contact analysis parameters. If the size of the shielding of the sheath to the isostatic pressure can be determined before the finite element analysis, and the pressure after shielding can be directly applied to the surface of the workpiece, the difficulty of contact analysis between the sheath and the workpiece can be avoided, and the calculation workload can be reduced. The shell member studied is a hyper-hemispherical shape, which is connected by a hemispherical shell and a cylindrical shell. Therefore, the isostatic pressure shielding effect of these two types of envelopes with different shapes is analyzed in this paper.

Plastic stress analysis of the inner and outer hemispherical shells In the process of isostatic pressing, the isostatic pressure acts on the surface of the inner and outer hemispherical shells, and the plastic deformation of the inner and outer hemispherical shells must first occur before the isostatic pressure can be transmitted to the inner workpiece of the sheath . Assuming that the reaction force of the workpiece to the sheath after the workpiece is compressed, the force conditions of the inner and outer sheaths are different.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com