Refractory Materials Molding

The forming of refractory materials refers to the process of processing the blank into a bad body of specified size and shape by means of external force and model. There are many molding methods. The traditional molding methods can be divided into semi-dry method (about 5% moisture content), plastic method (about 15% moisture content) and grouting method (about 40% moisture content) according to the moisture content of the billet. In the production of refractory products, the forming method is selected according to the properties of the blank, the shape, size and process requirements of the product.

1. Isostatic pressing method:

The isostatic pressing method is a method in which equal pressure is applied to the mud in all directions for molding. The commonly used stress transmission medium is liquid, such as oil, water or glycerin. Because the compressibility of brake fluid or anhydrous glycerin is very small, almost all the pressure can be transmitted to the elastic mold, so these two liquids are often used as pressure transmission medium.

The characteristic of isostatic pressing is that each part of the mud is pressed evenly and at a high pressure, so that the density of the green body obtained in this way is high and uniform, so that the deformation and shrinkage of the green body during the firing process are greatly reduced, and it will not The green body formed by the general molding method has firing cracks caused by the stress caused by the density difference. In addition, the pressurization operation of isostatic molding is simple, and the molding pressure is convenient to adjust; the rubber or plastic mold for molding is easy to manufacture and low in cost. It can be used repeatedly; no or less temporary binder can be used in the mud. Isostatic pressing can be used to press large and slender products with complex shapes that are difficult to form by general molding methods, such as long nozzles, submerged nozzles, tuyere bricks, and integral stoppers.

2. Ramming molding method:

The tamping method is a method of compacting and forming mud with manual, pneumatic or electric tamping hammers.

The pneumatic hammer is powered by compressed air, which is a commonly used power source in factories. The ramming forming method is generally used to form products with complex shapes and large volumes. The moisture content of the rammed mud is mostly controlled within the range of 4% to 6%. The critical particle size of the mud is larger than that of machine press molding. This is beneficial to increase the density of the green body. When ramming and molding, materials are generally added in layers, and attention should be paid to the close combination between layers.

Due to the high labor intensity of the ramming molding method, this molding method is currently used less. Only some special-shaped bricks will use this manual method.

3. Melting and casting method:

The melting and casting molding method is a molding method in which the batch material is melted at a high temperature and directly cast into a product. Because electric arc furnaces are commonly used to melt batch materials, the products formed by melting and casting are also called electric melting products.

The characteristic of melting and casting molding is that the high-temperature melt is directly poured into the mold for molding. This requires that the model has high fire resistance, good air permeability, high impact strength and thermal shock resistance, and does not react with the melt. Commonly used models are made of quartz sand, corundum sand or graphite plates.

Fused cast refractory products have the characteristics of large grain size, compact structure, high mechanical strength and good corrosion resistance, and are mainly used in the glass industry.

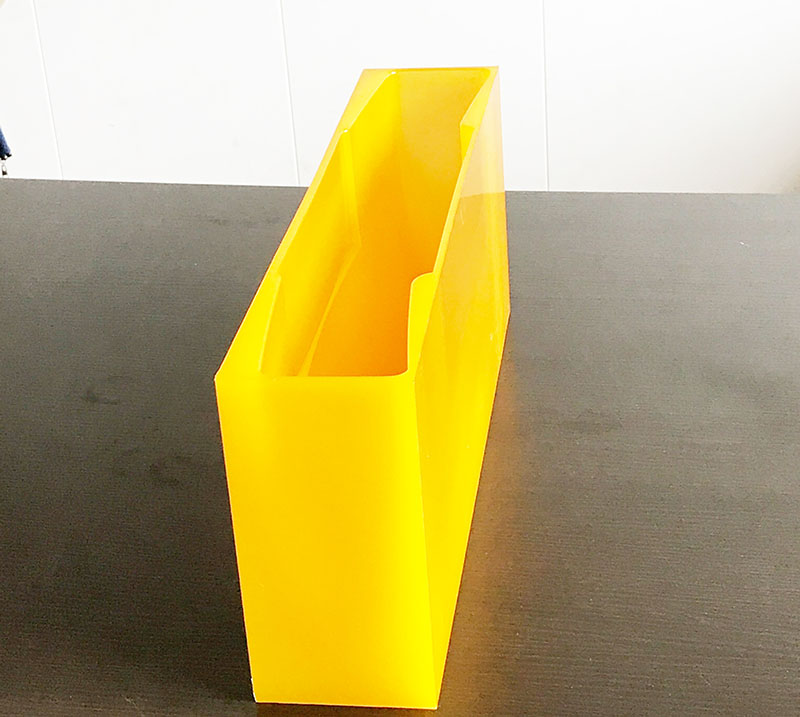

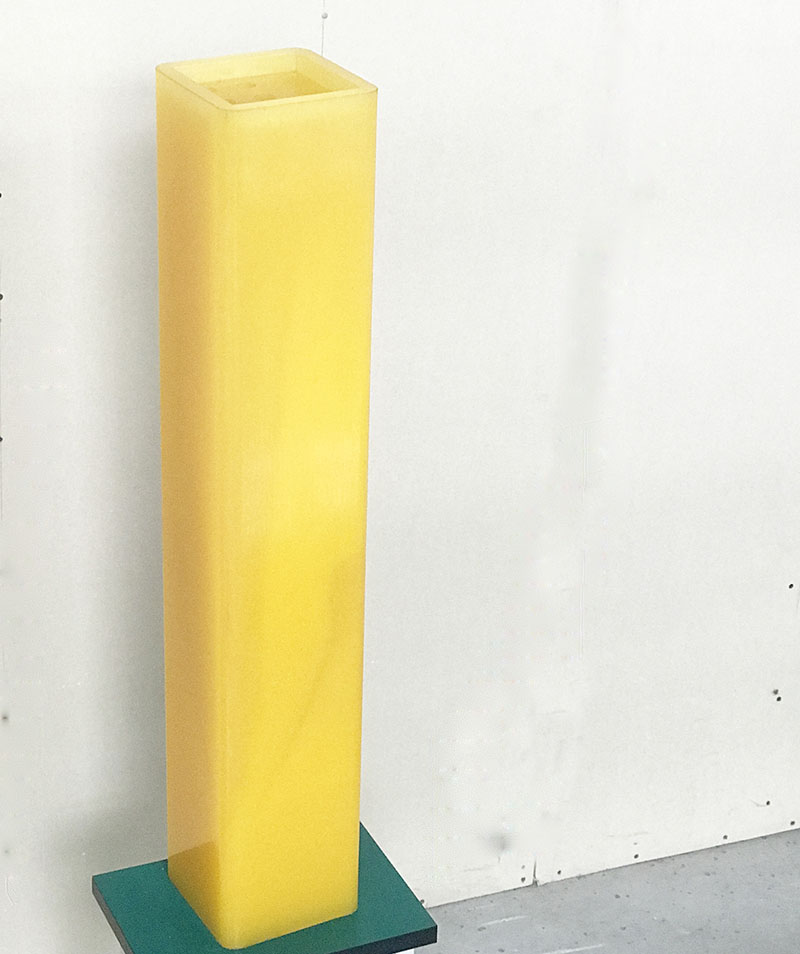

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com