Refractory- Isostatic Pressing Molding

The method of applying equal pressure in all directions of refractory mud is called isostatic pressing method. Commonly used pressure transmission medium is liquid, such as oil, water or glycerin. Because the compressibility of Chacha oil or anhydrous glycerin is very small, almost all the pressure can be transmitted to the elastic mold, so these two kinds of liquids are often used as the pressure transmission medium.

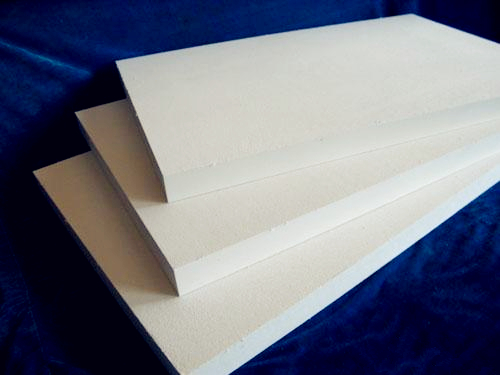

The biggest feature of isostatic pressing is that each part of the refractory mud material is under uniform pressure and the pressure is very high, so that the refractory body obtained in this way has a high and uniform density, so that the deformation and shrinkage of the green body during the firing process are greatly improved. Reduced, and there will be no firing cracks caused by the stress of the green body formed by the general molding method due to the density difference. In addition, the pressure operation of isostatic pressing is simple, and the pressure of refractory materials is easy to adjust; the rubber or plastic molds for molding are easy to manufacture, low in cost, and can be used repeatedly; no or less temporary binders are used in the mud.

Isostatic pressing can be used to press large and slender products with complex shapes that are difficult to form by general molding methods. Such as long nozzle, submerged nozzle, tuyere brick, integral stopper, etc.

On the basis of general isostatic pressing, hot isostatic pressing and explosive isostatic pressing forming technologies have been developed. Hot isostatic pressing is mainly used for superhard materials and difficult-to-sinter materials, and generally sintering and forming are completed at the same time. In addition, hot isostatic pressing of refractory materials is also used for re-densification of sintered products, bonding, and elimination of internal defects of products. Hot isostatic pressing can improve the mechanical properties of the product, reduce performance fluctuations, reduce the sintering temperature of the green body, and easily control the microstructure of the material.

Explosion isostatic pressure is to apply the high-pressure shock wave generated by the explosion to the liquid medium, and pressurize the refractory mold body at the same time, so that the refractory mixture is evenly pressed in all directions at the same time. The characteristics of explosive isostatic pressing are: simple device, no attached high-pressure system, high pressure generated by explosion, short molding time, high density and high hardness of the molded body. At present, the application of this forming method in refractory materials is still relatively small.

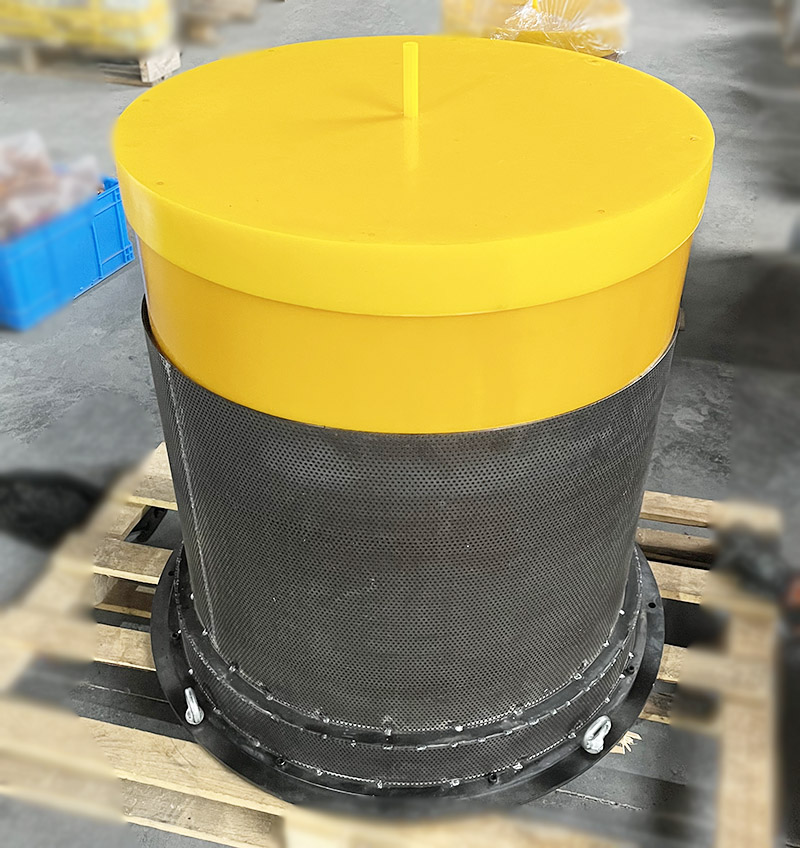

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com