Isostatic Pressing Method of Refractory Material

The isostatic pressing method is a method in which equal pressure is applied to the mud in all directions for molding. Commonly used pressure transmission medium is liquid, such as oil, water or glycerin. Because the compressibility of brake fluid or anhydrous glycerin is extremely small, almost all the pressure can be transmitted to the elastic mold, so these two liquids are often used as pressure transmission media.

The biggest feature of isostatic pressing is that each part of the mud is pressed evenly and at a high pressure, so that the green body obtained in this way has a high and uniform density, so that the deformation and shrinkage of the green body during the firing process are greatly reduced, and the pressure is not high. There will be firing cracks caused by the stress generated by the density difference of the green body formed by the general forming method. In addition, the pressurization operation of isostatic pressing is simple, and the molding pressure is convenient to adjust; the rubber or plastic molds for molding are easy to manufacture, low in cost, and can be used repeatedly; no or less temporary binders can be used in the mud. Isostatic pressing can be used to press large and slender products with complex shapes that are difficult to form by general molding methods, such as long nozzles, submerged nozzles, tuyere bricks, and integral stoppers.

According to the pressure medium and forming temperature, isostatic pressing can be divided into cold isostatic pressing (the medium is liquid at room temperature) and hot isostatic pressing (the medium is gas, and pressurization and heating are carried out at the same time). The production of refractories mainly adopts the cold isostatic pressing method. Therefore, the so-called isostatic pressing method refers to the cold isostatic pressing method.

The equipment used in the isostatic pressing method is an isostatic press, which applies Pascal's principle and relies on high-pressure liquid or gas to exert the same pressure on the material from all directions. Its equipment is mainly composed of elastic mold, cylinder (high pressure vessel), frame, hydraulic system and so on.

There are two cold isostatic pressing methods: wet bag method and dry bag method. Therefore, the molding equipment is also divided into wet bag cold isostatic press and dry bag cold isostatic press.

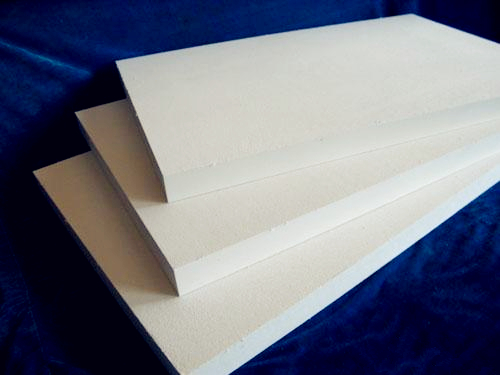

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold