Molding process and corresponding products:

1. Dry pressing

The powdery particles are compressed in the mold by using a relatively large pressure. The essence is that the particles are close to each other in the mold under the action of an external force, and the particles are firmly connected by internal friction and kept in a certain shape. It is mainly suitable for low-cost, mass production of mechanical seal rings, bulletproof plates, integral bulletproof chest plates, sandblasting nozzles, shaft sleeves, plates, faucet valve plates and other simple-shaped parts.

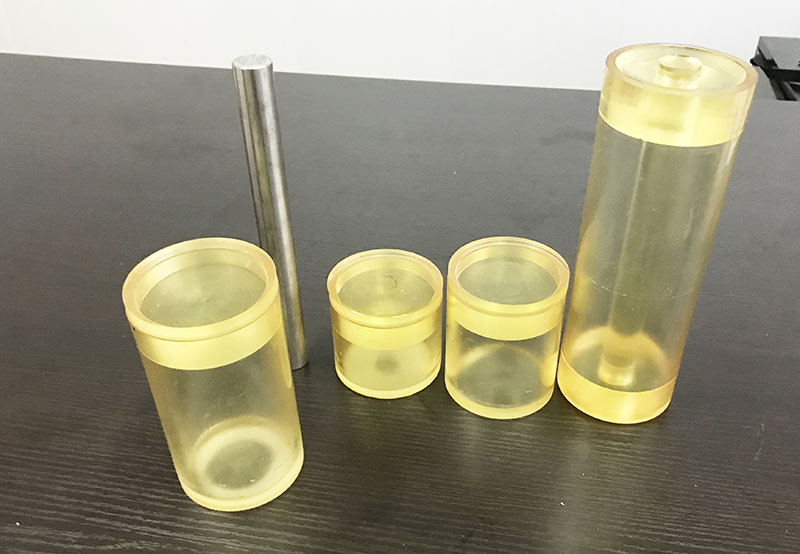

2. Isostatic pressing

It is a molding method that utilizes the incompressibility of liquid medium and the uniform transmission of pressure. Compared with the dry pressing method, the biggest feature of the isostatic pressing method is that the powder material is in a state of three-dimensional compressive stress, so the shape of the formed part The performance and quality have been significantly improved, and are often used in the production of grinding barrels, block hole heat exchange parts, thermocouple protection tubes, pipes, heat radiation tubes, large plates, and discs.

3. Grouting molding

By injecting the slurry into a porous mold made of gypsum abrasives, using the water absorption (solution) of the porous mold, the slurry is absorbed by the model on the side close to the mold wall to form a uniform green layer, and over time When the required thickness is reached, the excess slurry is poured out, and finally the blank layer continues to syneresis and separates from the model, and it is the blank after being removed from the model. It can not only make ceramic products with complex shapes, but also is good at making larger-sized ceramic products, such as thermocouple protection tubes, sagger crucibles, grinding buckets, sandblasting nozzles, pump casings, special-shaped parts, etc.

4. Extrusion molding

It is to put the vacuum-refined mud into the high-pressure extruder, and extrude it into a certain shape of green body through the extrusion nozzle (also called the die nozzle) under the action of external force. The extrusion nozzle is the forming mold. The nozzle can extrude green bodies of different shapes. It is suitable for forming tubular and cross-sectional parts, and the extruded parts are almost unlimited in length, such as chemical heat exchange tubes, ceramic rods, square beams, DPF (exhaust gas filter), ceramic membranes, plates, etc.

Jiangsu High Industry focuses on the research and production of isostatic pressing moulds, customizes various dry bag and cold isostatic pressing moulds, adapts to different models of various manufacturers at home and abroad, and deeply understands the needs of various industries. Alloy, graphite and other industries provide high-performance isostatic pressing mold rubber sleeves.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com