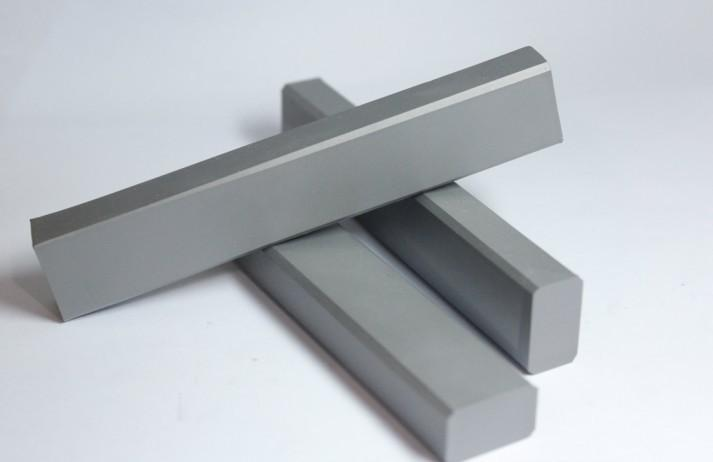

Tungsten Carbide and Cold Isostatic Pressing

Cold isostatic pressing dies are widely used in the isostatic pressing of cemented carbide powder. Cemented carbide has a wide range of applications, including engineering, machinery, automobiles, ships, optoelectronics, military and other fields. The cemented carbide industry consumes more than half of the total tungsten consumption. The basic information about cemented carbide is as follows:

1. Definition Cemented carbide (tungsten carbide) is an alloy that uses tungsten carbide powder (WC) as the main production material and cobalt, nickel, molybdenum and other metals as binders. The composition of tungsten carbide with high specific gravity is not much different. . Tungsten alloy is an alloy with tungsten as the hard phase and metal elements such as nickel, iron, and copper as the binder phase.

2. Features

1) High hardness (86-93HRA, equivalent to 69-81HRC). Under other conditions unchanged, the higher the tungsten carbide content, the finer the grain, the greater the hardness of the alloy.

2) Good wear resistance. The tool life of this material is 5-80 times higher than that of high-speed steel cutting; the life of abrasive tools produced by this material is 20-150 times higher than that of steel grinding tools.

3) Excellent heat resistance. Its hardness remains basically unchanged at 500°C, and is still very high at 1000°C.

4) Strong corrosion resistance. Under normal circumstances, it does not react with hydrochloric acid and sulfuric acid.

5) Good toughness. Its toughness is determined by the binder metal, and the higher the binder phase content, the greater the flexural strength.

6) High brittleness. It is difficult to make tools with complex shapes because cutting operations cannot be performed.

The traditional process can be divided into processes such as cold isostatic pressing and molding. Although it is rarely used, it is indispensable in some specific occasions. The CIP process of cemented carbide bar forming mainly includes pressing method, wet bag method and dry bag method.

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold