Powder Metallurgy

Powder metallurgy forming, divided into powder metallurgy pressing forming and powder metallurgy special forming two categories.

Powder metallurgy forming is the process of compacting metal powder body into a blank block with certain shape, size, density and strength. It is one of the basic processes of powder metallurgy process.

Powder pressing forming, also known as powder molding, abbreviated as pressing, it is the earliest forming method used in powder metallurgy production. In the late 18th and early 19th centuries, Russia and England used steel die pressing to make platinum products. Subsequently, the powder pressing forming method gradually improved, used to press a variety of oil bearing, powder metallurgy antifriction products, powder gold mechanical structure parts, etc. Since the 1930s, powder pressing forming has been more development, press and die design and other aspects of continuous improvement, can press complex shape parts, mechanization and automation degree is higher.

Powder metallurgy special forming is used for the shape, size and density of the blank block have special requirements. Powder cold isostatic pressing forming, powder rolling forming, powder extrusion forming, powder pouring and powder explosion forming, etc. Powder injection molding appeared in the 1970s, and metal powder injection molding appeared in the 1980s. Powder injection molding developed rapidly in the United States and Japan, and it can produce high-precision, irregular shape products and thin-walled parts.

The Importance of Powder Metallurgy Technology

As the history of powder metallurgy development has been extended for a long time, with the development of powder metallurgy technology, metal dust has been extended to refractory metal compound powder, ceramic powder and coating powder, processing

Powder metallurgy products can be used without further processing, and several processed products can be subsequently treated as required. Modern technology of powder metallurgy has an important mark in its development, now powder metallurgy

Now the powder metallurgy technology, has been applied in the national industry, the processing of hard alloy is known as the industrial revolution of cutting processing, the powder metallurgy machine parts used in the industry is the development of new materials and new processes of oil pump gear, with higher output, has become a new material of historical significance, As an advanced technology of modern metallurgy, powder metallurgy plays an increasingly important role.

The addition of dry materials, powder metallurgy is no need to cut the new art, dry manufacturing machine parts, can greatly reduce the amount of plus, save mechanical straight, save metal materials, powder metallurgy in the national economic situation, as well as the field of science and technology are more and more important, powder metallurgy process involves powder preparation, powder metallurgy rapid powder grinding technology is relatively simple, This type of grinding technique, in which liquid metal or alloy is pulverized and quickly condensed, effectively reduces segregation of alloy components, resulting in a relatively uniform alloy powder composition.

Because the powder medium used is different, the powder method used in powder metallurgy grinding technology also has a variety of choices, the gas pressure in the gas powder method, generally must reach a certain value, on the basis of which the surface can be obtained, smooth dust particles used in powder metallurgy, powder method uses high density water as the powder medium, The powders produced by this technique have significantly different physical, chemical and mechanical properties.

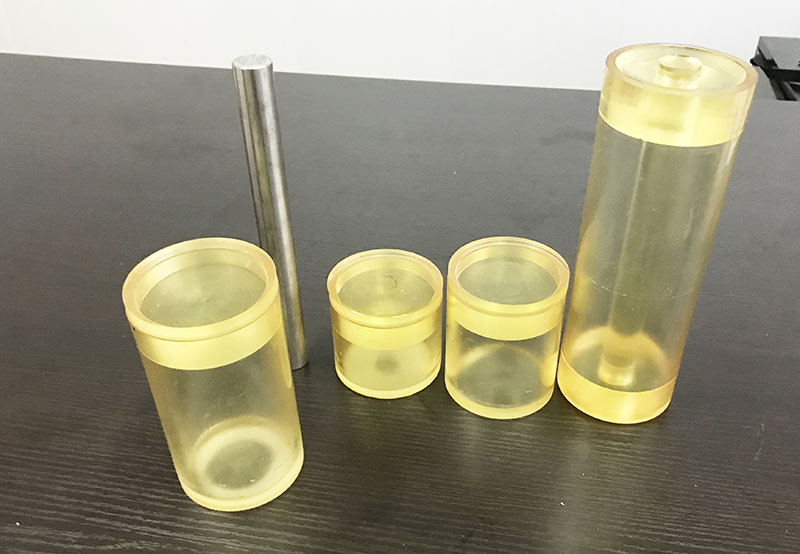

Jiangsu High Industry on the research and development and production of high-performance polyurethane isostatic pressing molds. Through in-depth cooperation with many isostatic pressing equipment manufacturers and in-depth study of the industry, the developed isostatic pressing polyurethane mold series products have the characteristics of long service life, high precision, small deformation, easy demoulding, etc., and are widely used in ceramics, etc. Static pressing mould, cemented carbide isostatic pressing mould, rare earth permanent magnet material isostatic pressing mould, graphite isostatic pressing mould, etc.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Polyurethane Products Pu Products Rubber Mold Plastic Mold