Isostatic Pressing Bags for Isostatic Pressing Graphite

Isostatic graphite characteristic use production process

Isostatic graphite is a new type of graphite material developed in the 1940s, which has a series of excellent properties. Isostatic graphite has good heat resistance. In an inert atmosphere, as the temperature rises, its mechanical strength increases instead, reaching the highest value at about 2500 ° C. Compared with ordinary graphite, the structure is fine, dense and uniform. Good resistance; low thermal expansion coefficient, excellent thermal shock resistance; isotropy, strong chemical corrosion resistance, good thermal conductivity and electrical conductivity; excellent machining performance. It is precisely because of this series of excellent properties that isostatic graphite is widely used in the fields of chemical industry, semiconductor, electrical, metallurgy, machinery, nuclear energy and aerospace, and, with the development of science and technology, the application field is still expanding .

1. The main application of isostatic graphite

1.1 Graphite for solar cells and semiconductor wafers

In the solar energy and semiconductor industries, a large amount of isostatic graphite is used to make graphite components in the thermal field of single crystal Czochralski furnaces, heaters for polysilicon melting and casting furnaces, heaters for compound semiconductor manufacturing, crucibles and other components. In recent years, solar photovoltaic power generation has developed rapidly, and the production of monocrystalline silicon and polycrystalline silicon in the photovoltaic industry has a huge demand for graphite. At present, both monocrystalline and polycrystalline silicon products are developing toward large-scale and high-end products, and there are higher requirements for isostatic graphite, namely: larger specifications, higher strength, and higher purity.

1.2 Nuclear graphite

Isostatic graphite has moderate mechanical properties, particularly excellent high-temperature mechanical properties, high thermal conductivity, and low linear expansion coefficient. In the high-temperature gas-cooled reactor, it is mainly used as a reflector, a moderator, and a structural material in the active area, and together with the nuclear fuel, it constitutes a nuclear fuel assembly. At a temperature of 400~1200°C, it is exposed to high-energy γ-rays and fast neutrons for several years, which is easy to cause radiation damage, thereby changing the structure and properties of graphite, so the material is required to have a high degree of graphitization. , good isotropy, uniform composition, low elastic modulus. At present, my country can only produce a small amount of nuclear graphite for high-temperature gas-cooled reactors, mainly relying on imports.

1.3 Electrode graphite

Graphite has no melting point, is a good conductor of electricity, has good thermal shock resistance, and is an excellent electrode material for EDM.

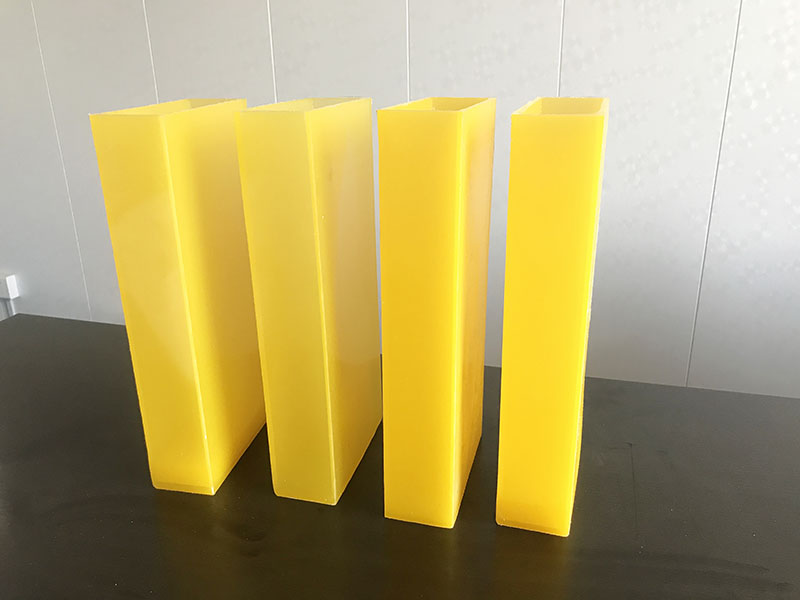

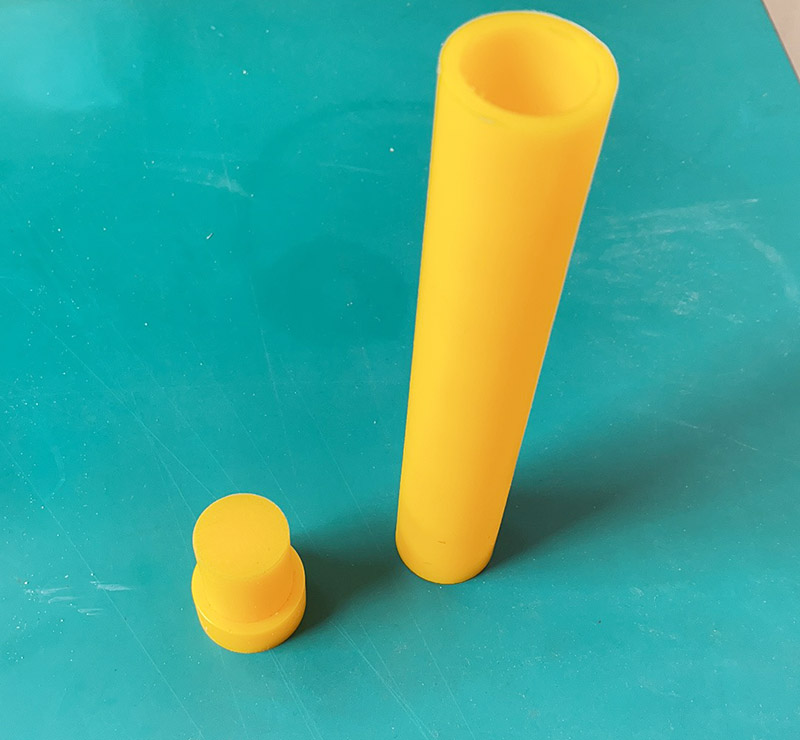

Jiangsu High Tech Co., Ltd. is located in Zhenjiang, Jiangsu. It is a high-tech enterprise that develops and produces high-performance polyurethane products, cold isostatic pressing molds and cold isostatic pressing machines. The company's main products are polyurethane isostatic pressing molds and cold isostatic pressing machines. The company's products are widely used in all walks of life in China and exported to more than 30 regions around the world. They are widely praised by customers for their excellent quality and good service. The company always adheres to the product concept of "quality first" and has a deep understanding of customer needs. The company has been committed to the research and development and production of high-performance polyurethane elastomer molds for many years, and solves various design and production problems of polyurethane elastic molds for isostatic pressing users. The company has mature production and processing technology and a complete set of experimental equipment for mold elastomer analysis. In order to ensure the excellent impact resistance, abrasion resistance, cutting, tear resistance and clarity of the product and excellent dimensional stability. Its products are widely used in magnetic materials, ceramics, cemented carbide, high temperature refractory materials, rare earth permanent magnets, carbon materials, rare metal powders and other industries.

Compare to traditional rubber cold isostatic pressing bags, the polyurethane CIP bags have significant advantages. As a new polymer material, polyurethane products feature smooth surface, wearing-resistant, anti-fatigue, low deformation rate. The surface of pressed products with polyurethane bags is much smoother than that pressed with rubber bags, thus it possesses better looks and less postprocessing is required. It’s an ideal tool for powder material forming by press process, which can help a company reduce cost and increase efficiency.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com