Ceramic Forming Method

1) Compression molding is a method of adding an organic binder to the powder, filling it into a metal model, and pressing it to make a molded body with a certain strength. This method is often used for mass-produced products in relatively simple shapes such as refractory materials, ceramic tiles, electronic ceramics, and nuclear fuel particles. The advantage is that the price is cheap and the dimensional error of the molded body is small. The pressure is within the range of 200-2000 kg/cm2.

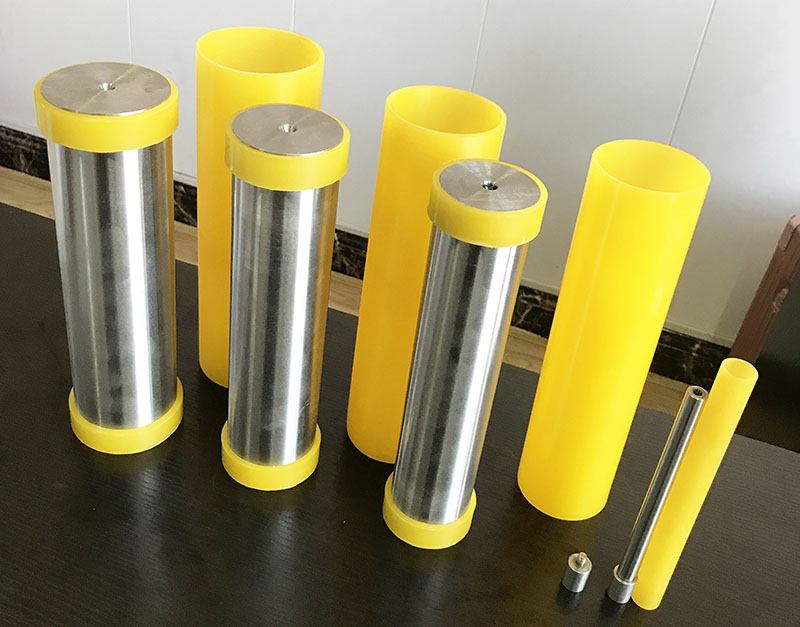

2) Isostatic pressing is a method to obtain a uniform powder compact. Because it uses a rubber bag (mold), it is also called the plastic bag forming method. In this method, the powder is put into a rubber bag, and then the rubber bag containing the powder is placed in a hydraulic chamber for molding. The pressure in the hydraulic chamber is evenly pressed on the powder, so a good molded body can be obtained.

3) Extrusion is a method of extruding the kneaded plasticity out of the die hole. Drainage pipes, hollow tile pipes, furnace core pipes and other products whose central axis is at right angles to the section are usually formed by this method. Recently, ceramic honeycomb body for automobile exhaust purification is a good application example.

4) Grouting forming is to make fluid mud with water etc., inject the mud into the porous gypsum model, the water penetrates into the gypsum model body through the contact surface, and forms a hard layer on the surface. This is a molding method in which the shape of the inner surface of a plaster mold is the same as that of a molded body. It is divided into double-sided grouting method (solid grouting method) and single-sided grouting method (hollow grouting method). This method was used very early in the production of ceramics.

5) Hot die casting is a method of adding plastic to the powder and molding it in the same way as resin molding. Although this method is suitable for the forming of complex parts, if the amount of binder exceeds 15-25%, it will be difficult to degrease. At present, this method is not suitable for large and thick-walled products.

Principle of isostatic pressing of ceramics Isostatic pressing (isostatic pressing) is also called hydrostatic pressing. It is a molding method that utilizes the incompressibility of liquid medium and the uniform transmission of pressure, that is, the pressure on the sample in the high-pressure container is the same as that in the still water at the same depth, so it is called hydrostatic pressure or Isostatic pressing. The molding process obtained according to this principle is called hydrostatic pressing, or isostatic pressing.

Cold Isostatic Pressing bags, CIP bags, molds, toolings