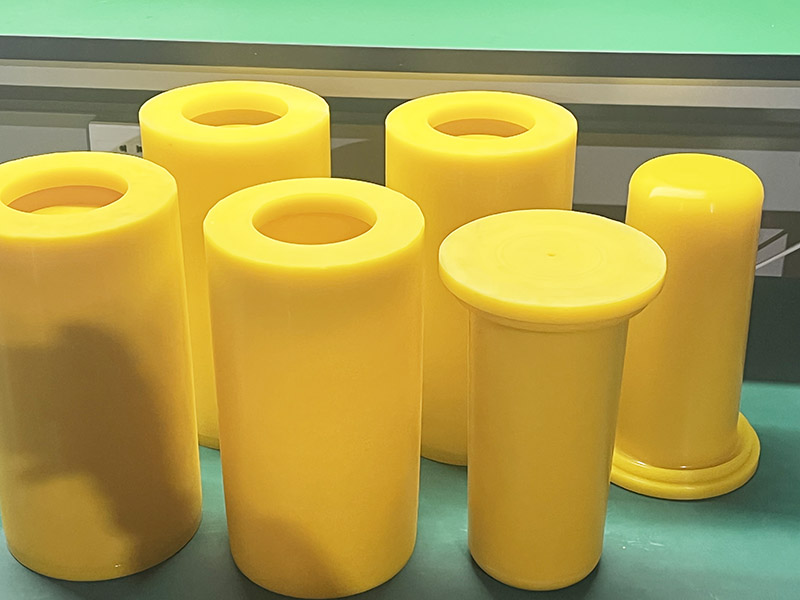

Isostatic Pressing Zirconia Ceramic Plunger Mold

Zirconia ceramic plunger is assembled by ceramic metallization bonding, welding, mosaic and nesting technology. Zirconia ceramic plunger forming process includes dry pressing forming, isostatic pressing forming, grouting forming, hot pressing casting forming, casting forming, and so on, which is an ideal substitute for similar metal pumps.

The advantages of Zirconia ceramic plunger

1. The pump body structure is finely sealed with the product structure, which is easy to disassemble.

2. The ceramic plungers have been tested for corrosion resistance, acid, and alkali resistance, and their indexes have exceeded the metal plungers.

3. The ceramic plunger is made of high-performance technical ceramic materials, which have the properties of high hardness, wear resistance, high-temperature resistance, corrosion resistance, and so on. These properties ensure the reliable performance of the material.

4. The working face of the ceramic plunger has the function of self-lubrication, which changes the mechanism of sliding friction and lubrication of the traditional piston pump.

5. The surface of the inner cavity adopts a fluid-structure, and there are no dead corners and grooves. The inner cavity surface and plunger surface are machined to the mirror surface by advanced high-precision internal and external circular grinder, and the outer surface is vibrating and polished to facilitate cleaning and disinfection.

Application fields of zirconia ceramic plunger: ultrafine grinding equipment, fine chemical industry, electronic slurry, semiconductor, new energy, nano new material, medical plunger pump, high pressure water pump, high pressure injection machine, high pressure water cutting machine, lithium battery pump, Metering pumps, precision casting, structural ceramics, refractory materials, electronic communications, sensitive ceramics, petrochemicals, aerospace, machinery manufacturing, optical fiber connectors, battery materials and other high-end fields.

CIP bags, Cold Isostatic Pressing bags, molds, toolings

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com