The Methods of Industrial Ceramics Molding and The Uses of Industrial Ceramics

Industrial ceramics, that is, ceramics for industrial production and industrial products. It is a kind of fine ceramics, which can play mechanical, thermal, chemical and other functions in application. Because industrial ceramics have a series of advantages such as high temperature resistance, corrosion resistance, wear resistance, and erosion resistance, they can replace metal materials and organic polymer materials in harsh working environments, and have become traditional industrial transformation, emerging industries and high-tech industries. It is an indispensable and important material, and has very broad application prospects in the fields of energy, aerospace, machinery, automobiles, electronics, and chemicals. Use corrosion-resistant ceramics with good chemical stability in contact with biological enzymes to produce metal smelting crucibles, heat exchangers, biological materials such as dental artificial paint joints, etc., and use unique ceramics that capture and absorb neutrons to produce various nuclear materials Reversible structural materials, etc.

The Methods of Industrial Ceramics Molding

1. Dry pressing method of industrial ceramics

"Dry pressing molding" uses pressure to press industrial ceramic powder into a green body of a certain shape. In fact, under the action of external force, the powder particles are brought close to each other in the mold, and are firmly combined by internal friction to maintain a certain degree of stability. shape.

The main defect in the dry-pressed green body is lamination, which is due to the internal friction between the powder and the friction between the powder and the mold wall, resulting in pressure loss inside the green body.

The advantages of dry pressing of industrial ceramics are: the size of the green body is accurate, the operation is simple, and it is convenient to realize mechanized operations; the content of moisture and binder in the dry pressing green body is small, and the drying and firing shrinkage is small.

It is mainly used to form products with simple shapes, and the aspect ratio is small. The increased production cost caused by mold wear is the disadvantage of dry pressing.

2. Isostatic pressing of industrial ceramics

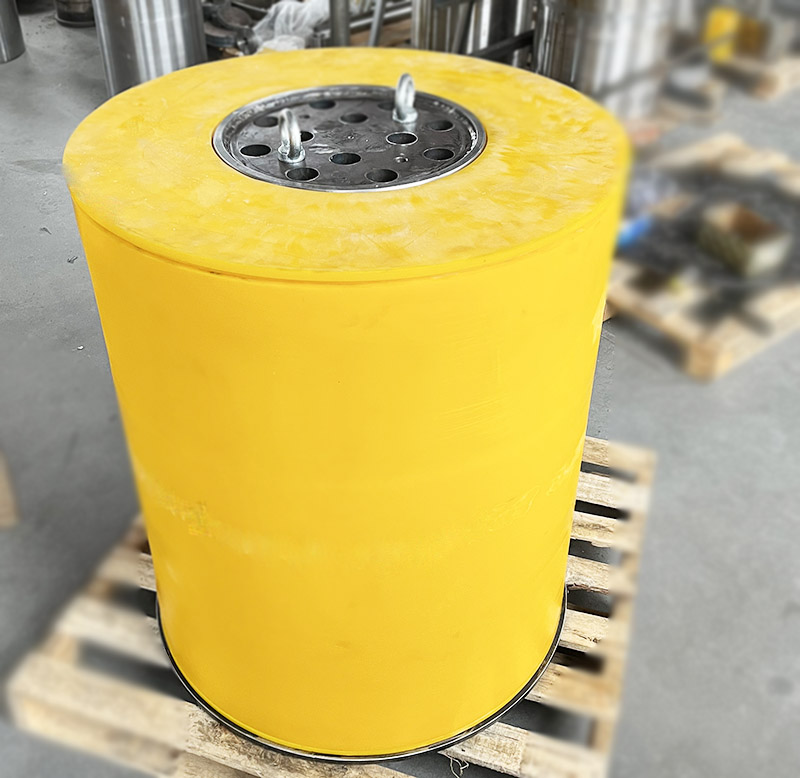

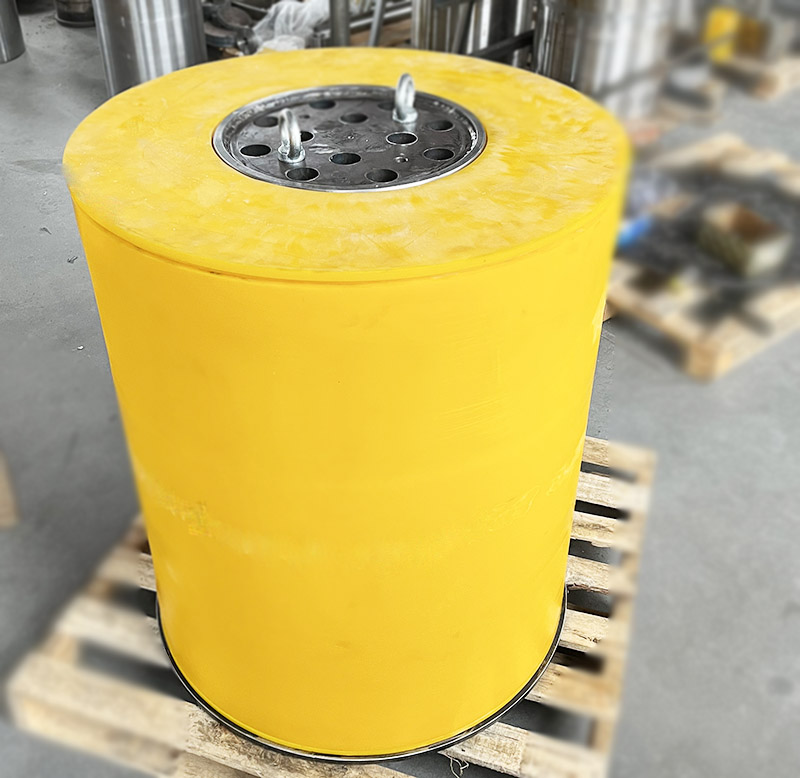

"Isostatic pressing" is a special forming method developed on the basis of traditional dry pressing.

It uses the fluid to transmit pressure, and applies pressure evenly to the powder in the elastic mold from all directions. Due to the consistency of the internal pressure of the fluid, the pressure on the powder in all directions is the same, so the difference in the internal density of the green body can be avoided.

Wet bag isostatic pressing: products with complex shapes can be formed, but it can only be operated intermittently.

Dry bag isostatic pressing: It can realize automatic continuous operation, but it can only form products with simple shapes such as square, round, and tubular cross-sections.

Isostatic pressing can obtain a uniform and dense green body, and the sintering shrinkage of industrial ceramics is small and uniform in all directions, but the equipment is more complicated and expensive, and the production efficiency is not high, so it is only suitable for the production of materials with special requirements.

What are the uses of industrial ceramics

Industrial ceramics are mainly ceramic products made by traditional techniques, and ceramic materials used in industry through high-tech and new techniques. Industrial ceramics are also divided into six types: architectural ceramics, sanitary ceramics, chemical ceramics, chemical ceramics, electrical ceramics, refractory materials and special ceramics, each of which has different functions. the

Chemical ceramics: mainly used in the chemical industry to hold some acidic materials, etc. Chemical ceramics have relatively less connection with life.

Chemical ceramics: the main place of application is the laboratory, used for research and so on.

Electric porcelain: It is mainly used in the electric power industry as an insulator on high-voltage wires.

Refractory materials: mainly used in high temperature work.

Special ceramics: mainly used in various technological industries, developed with the rapid development of modern electrical appliances, radio, aviation, atomic energy, metallurgy, machinery, chemical and other industries, as well as electronic computers, space technology, new energy development and other science and technology. The main raw materials used in these ceramics are no longer clay, feldspar, quartz, and some clay or feldspar are also used in some blanks, but more pure oxides and raw materials with special properties are used.The types of industrial ceramics are different, so the manufacturing methods are also different; the functions are different, and the range of use is very wide.

Cold Isostatic Pressing Bags, CIP bags, molds, toolings

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com