Characteristics and Uses of Graphite

Due to the above-mentioned excellent properties of graphite, it is widely used in modern industry.

1. As a refractory material: Graphite and its products have the properties of high temperature resistance and high strength. They are mainly used to manufacture graphite crucibles in the metallurgical industry. In steelmaking, graphite is often used as a protective agent for steel ingots and as the lining of metallurgical furnaces.

2. As a conductive material: in the electrical industry, it is used to manufacture electrodes, brushes, carbon rods, carbon tubes, positive electrodes of mercury rectifiers, graphite gaskets, telephone parts, and coatings for TV picture tubes, etc.

3. As a wear-resistant lubricating material: graphite is often used as a lubricant in the machinery industry. Lubricating oil often cannot be used under conditions of high speed, high temperature, and high pressure, while graphite wear-resistant materials can work at a high sliding speed at a temperature of 200~2000°C without lubricating oil. Many equipments conveying corrosive media widely use graphite materials to make piston cups, sealing rings and bearings, and they do not need to add lubricating oil during operation. Graphite milk is also a good lubricant for many metal processing (wire drawing, tube drawing).

4. Graphite has good chemical stability. Specially processed graphite has the characteristics of corrosion resistance, good thermal conductivity, and low permeability. It is widely used in the production of heat exchangers, reaction tanks, condensers, combustion towers, absorption towers, coolers, heaters, and filters. , Pump equipment. Widely used in petrochemical, hydrometallurgy, acid-base production, synthetic fiber, papermaking and other industrial sectors, it can save a lot of metal materials.

5. For casting, foundry, molding and high-temperature metallurgical materials: due to the small thermal expansion coefficient of graphite and its ability to withstand rapid cooling and rapid heat changes, it can be used as a casting mold for glassware. After using graphite, black metal can be used to obtain castings with accurate dimensions and smooth surfaces. It has a high efficiency and can be used without processing or with a little processing, thus saving a lot of metal. In the production of cemented carbide and other powder metallurgy processes, graphite materials are usually used to make boats for compression molding and sintering. Crystal growth crucibles for monocrystalline silicon, regional refining vessels, bracket fixtures, induction heaters, etc. are all processed from high-purity graphite. In addition, graphite can also be used as graphite insulation boards and bases for vacuum smelting, high temperature resistance furnace tubes, rods, plates, grids and other components.

6. Used in atomic energy industry and national defense industry: Graphite has a good neutron moderator and is used in atomic reactors. Uranium-graphite reactors are currently the most widely used atomic reactors.

Isostatic graphite is a new product developed in the past 50 years in the world, and is closely related to today's high technology. It not only has great achievements in civilian use, but also occupies an important position in national defense. It is a new type of material and is eye-catching. It is an irreplaceable material for manufacturing single crystal furnaces, metal continuous casting graphite crystallizers, and graphite electrodes for EDM.

There are three main methods of forming graphite products:

1. Hot extrusion molding: such as the production of graphite electrodes for steelmaking.

2. Compression molding: used for aluminum carbon and electric carbon products.

3. Isostatic pressing: The raw materials for isostatic graphite production are under pressure in all directions, and the carbon particles are always in a disordered state, so that the production

There is little or no difference in performance between products, and the performance ratio in the direction is not greater than 1.1. Known as: "isotropic".

Isostatic graphite is widely used, and many isostatic graphite manufacturers have emerged. Due to the late start of domestic manufacturers, the production process of domestic isostatic graphite lags behind that of foreign countries. The indicators of isostatic graphite produced abroad are better than domestic ones. The difference between isostatic graphite and high-purity graphite lies in the different production processes. The density and performance of isostatic graphite are better than high-purity graphite.

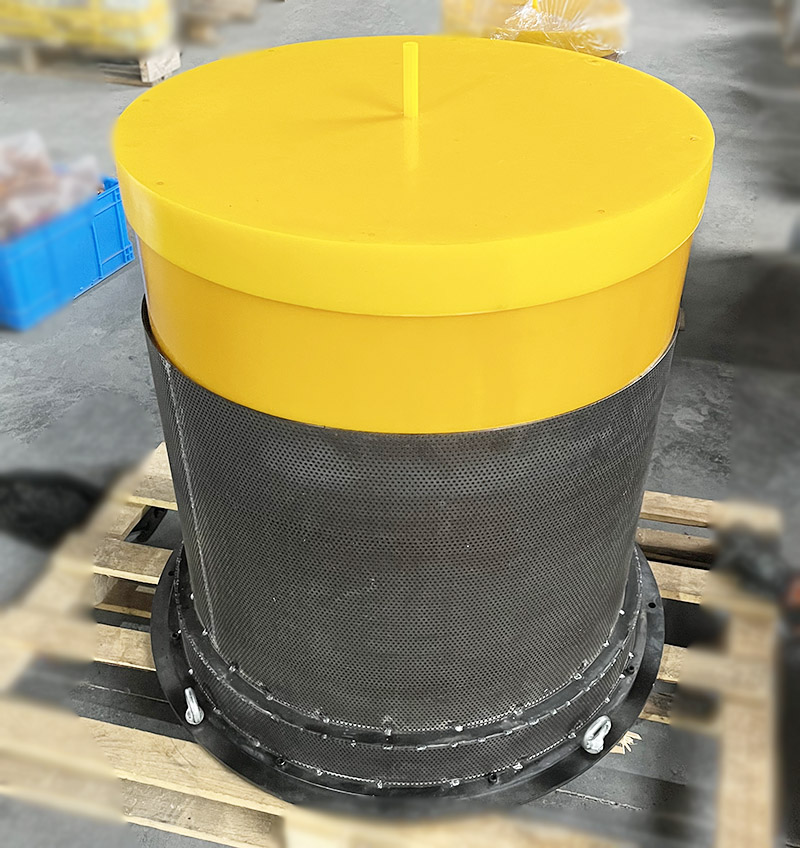

Cold Isostatic Pressing bags, molds, toolings

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com