About Graphite Crucible

The main raw material of graphite crucible is crystallized natural graphite. Therefore, the original physical and chemical properties of natural right graphite are maintained.

That is, it has good thermal conductivity and high temperature resistance, small coefficient of thermal expansion when used at high temperature, and has certain strain resistance to rapid heating and rapid cooling. It has strong corrosion resistance and excellent chemical stability to acid and alkali solutions.

Crucibles are available in many types and sizes and are not limited by production scale, batch size, or the type of material to be melted in the application. They can be selected at will, are highly applicable, and guarantee the purity of the melted material.

The use of graphite crucible is mainly for the melting of metals as well as experiments. Because of its excellent performance as follows: good electrical and thermal conductivity, high purity, durability, stable and reliable quality, it is used for melting non-ferrous metals such as gold, silver, copper, aluminum and lead, as well as carbon steel and various rare and precious metals; special graphite crucible for laboratory and analysis test.

The main raw materials of graphite crucible are silicon carbide, refractory clay, graphite, graphite, tar and asphalt, etc. It is widely used in melting and casting of various non-ferrous metals and can be divided into natural and artificial graphite. The graphite crucible has a long service life, significantly reduces the combustion consumption, reduces the manual labor intensity, improves the working efficiency and reduces the cost.

There are three methods of forming crucibles, the more primitive and ancient method of forming is hand molding. This traditional molding method has not been completely eliminated yet. The reason is that a practical process equipment and molds have not been developed for shaped crucibles. The second is the spin molding method. This molding method is still commonly used since the 1930s. It is developed on the basis of hand molding. The third is the isostatic molding method. This molding method is a new process molding method developed on the basis of spin molding in the late 60s and early 70s. The products have obvious advantages: high density, stable quality and good thermal conductivity, which can really save energy for enterprises.

Features of graphite crucible

1. High thermal conductivity: shortening melting time due to the use of raw materials such as graphite with high thermal conductivity.

2. Thermal shock resistance: high thermal shock resistance, not easy to break regarding rapid cold and heat.

3. High heat resistance: can resist high temperature from 1200 to 1600℃.

4. Erosion resistance: strong against erosion of molten soup.

Advantages of the isostatic graphite crucible.

1. Good thermal conductivity, the crucible is made of highly thermally conductive material with compact structure and fast thermal conductivity.

2. Longer crucible life than ordinary crucibles, compared to ordinary clay graphite crucibles, which can increase the crucible life by more than 5 times

3. High density of isostatic graphite crucible: using advanced isostatic pressing process, the material is dense and uniform without defects.

4. High temperature resistance: use temperature 400-1700 degrees Celsius, different ranges available.

5. Energy saving and environmental protection: fast heat conduction can save a lot of fuel and reduce waste gas pollution. Significant reduction of reactive power loss by induction heating at appropriate resistivity.

6. High oxidation resistance: advanced oxidation resistance mechanism, so that the graphite in the crucible is well protected.

7. High strength: material selection, high pressure pressing, reasonable combination, good high temperature strength, scientific product shape, high pressure carrying capacity.

8. Anti-corrosion: advanced material formulation, effective resistance to the physical and chemical effects of the melt.

9. Low slag sticking: less slag hangs on the inner wall, which considerably reduces the possibility of thermal resistance and cracks extending the crucible and always keeps the crucible capacity rationalized.

10. Metal saving: effective inhibition of metal oxidation due to the presence of special elements in the material.

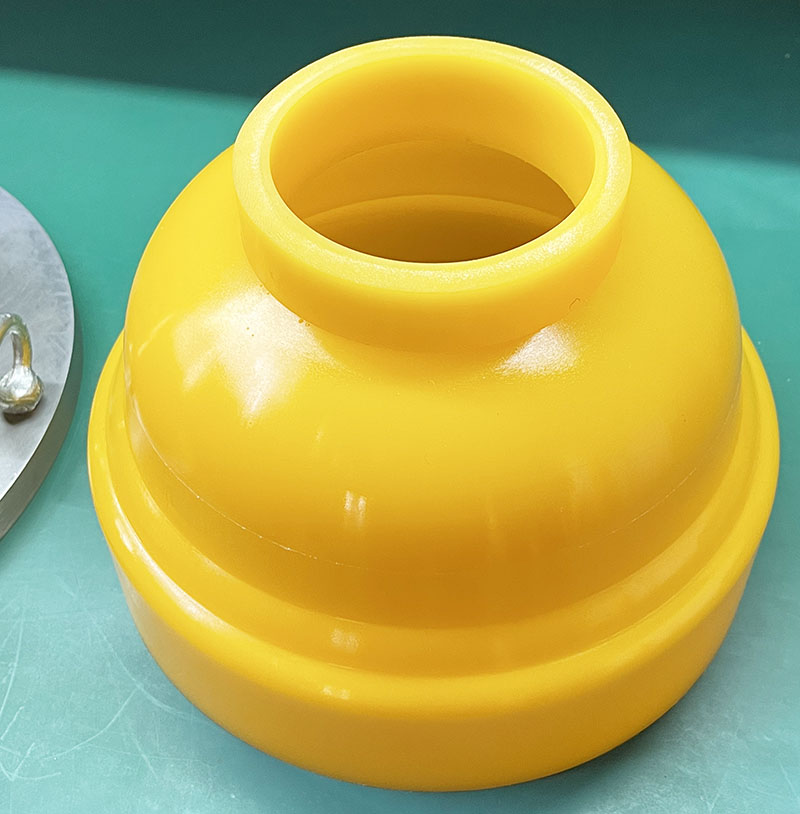

CIP mold, bag, tooling, Cold Isostatic Pressing bags,molds, toolings

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com